- Home

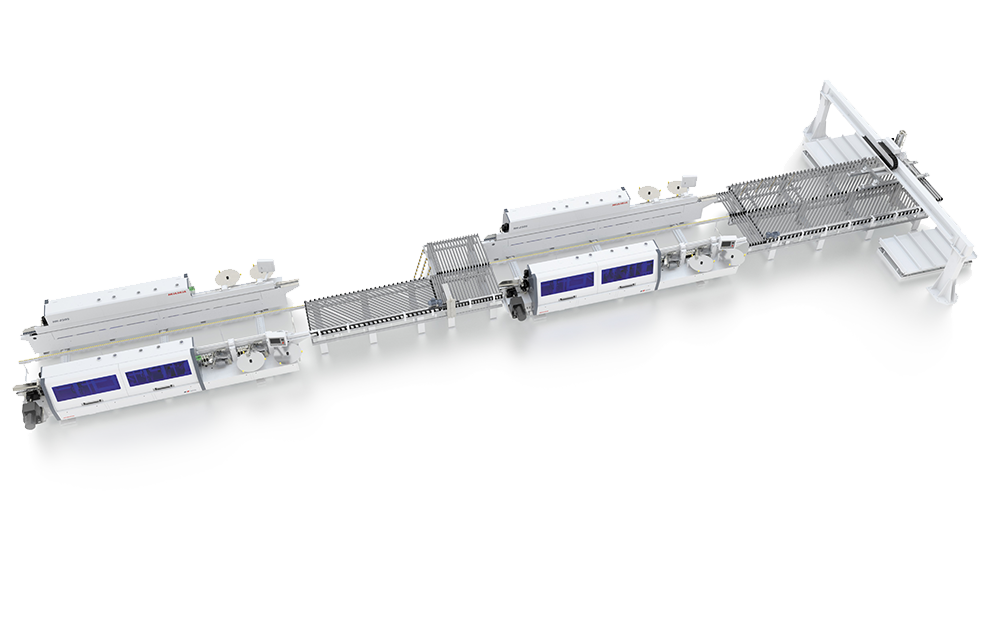

- Edge Banding Machine Line

- Double Sides Edge Banding Machine Line

- HUAHUA Double Sides Edge Banding Machine Line

HUAHUA Double Sides Edge Banding Machine Line

HUAHUA Double Sides Edge Banding Machine Line

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

Independent Research and Development

Furniture production line, developed and assembled by HUAHUA. All hardware and software are independently developed and produced, intelligent/automatic/efficient/economical;

On-site installation and commissioning of the construction team; engineer training; full service;

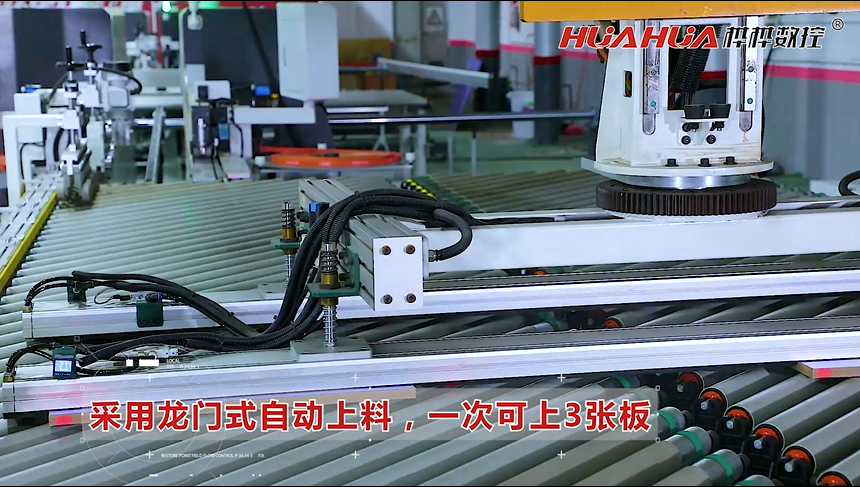

Gantry feeder loading

Adopt gantry feeder automatic loading ,one time can load 3pcs panels

Infrared sensor

The feeding conveyor is equipped with infrared sensor to prevent the error of conveying collision panels

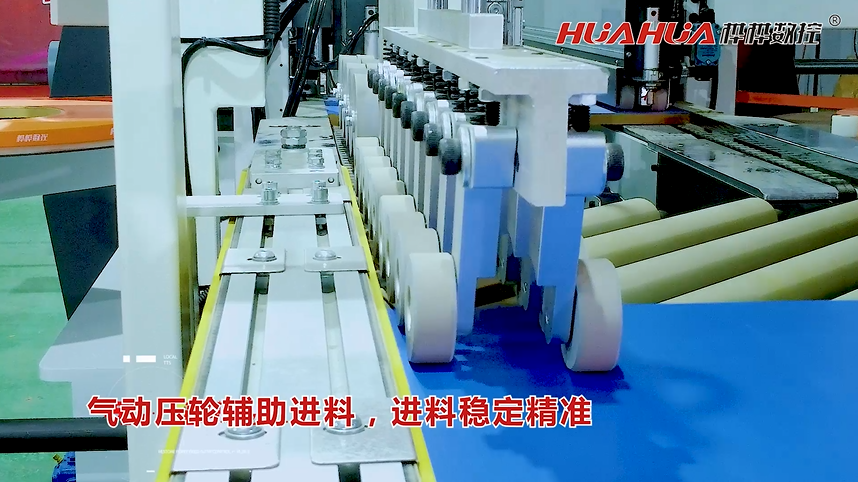

Pneumatic pressure wheel assists feeding

Pneumatic pressure wheel assists feeding, stable and accurate feeding

Double Sides Edge Banding Machine

Automatic Positioning:

Precise ball screw drive, fast and precise positioning with one button;

Processing Range:

Processing width 285-2650mm.

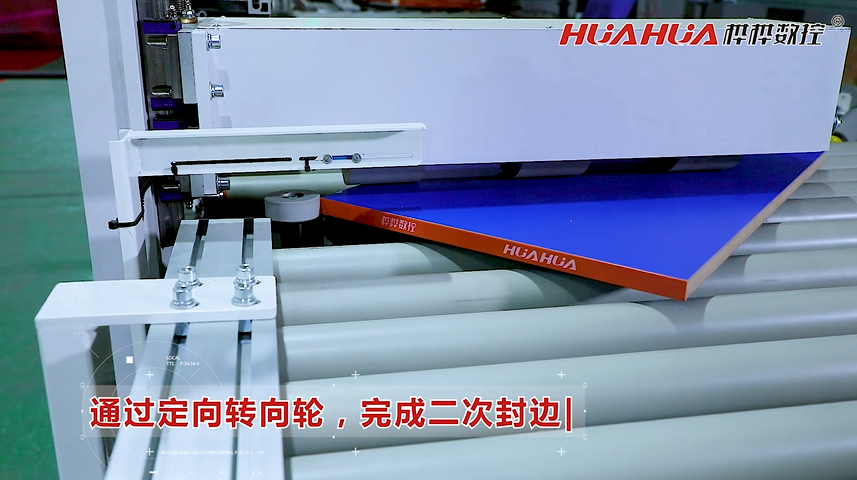

Directional steering wheel

Through the directional steering wheel, the panel is rotated 90 degrees to complete the secondary edge banding

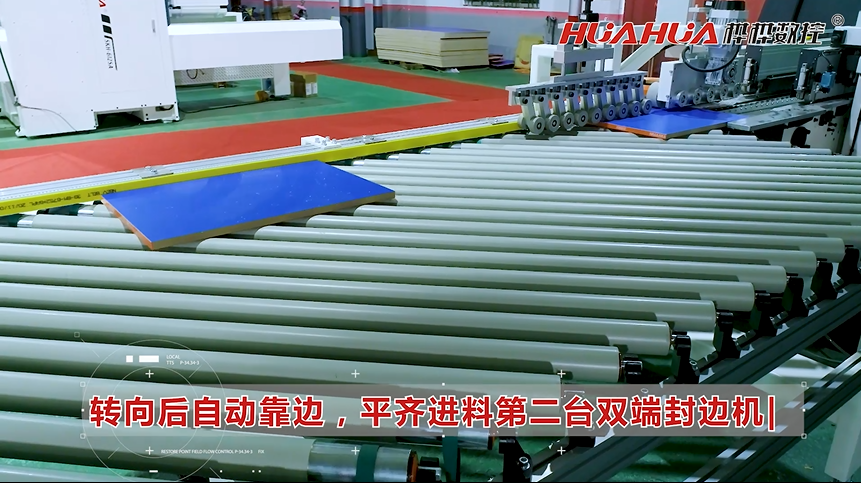

Automatic side align

Automatically move to the side after turning, side align feeding to second double side edge banding machine

Finished at Once

Complete the edge banding of 4 sides of the panel at one time, saving time and labor, and being efficient.

Technical Specifications

The whole line covers an area of 162 square meters (27X6 meters),complete the edge banding of 4 sides of the panel at one time, saving time and labor, and being efficient.

Applications

Automatic edge banding machine, meet various edge banding needs, the necessary machine for furniture, saving time, labor cost