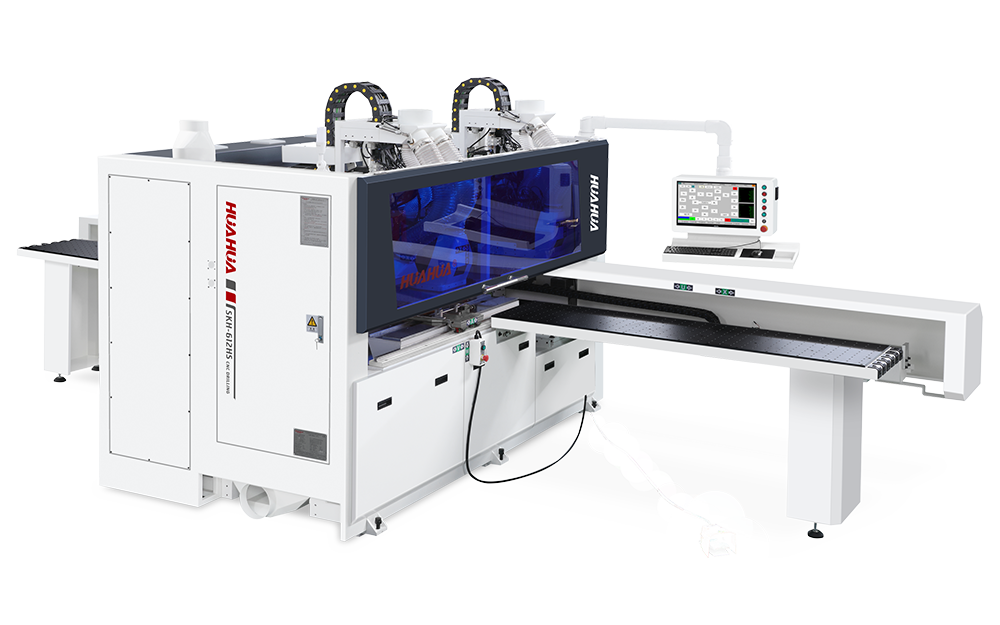

SKH-612NST

SKH-612NST

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

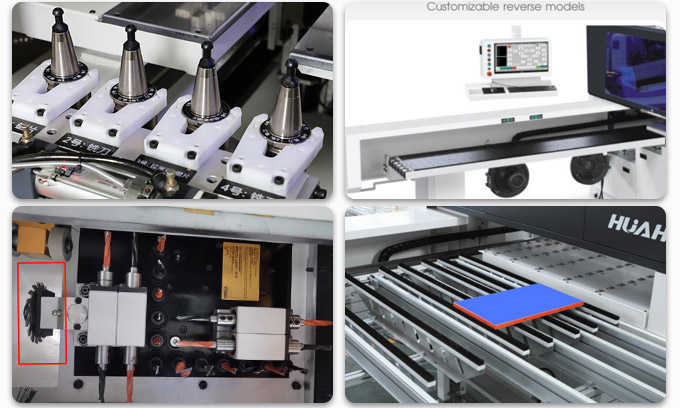

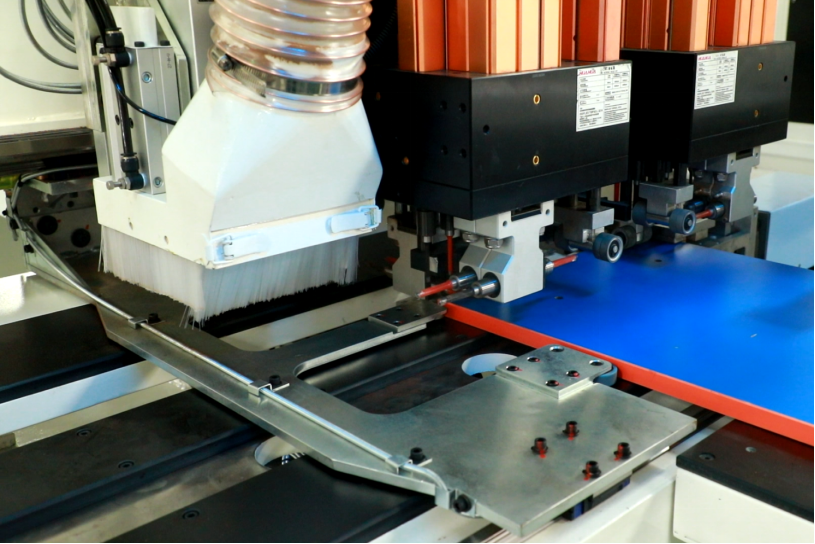

Four tool magazines with automatic tool changing

The straight-line four-tool magazine allows for continuous and efficient processing, which can be used to make horn handles, embedded handles, laminos, and a variety of invisible parts.

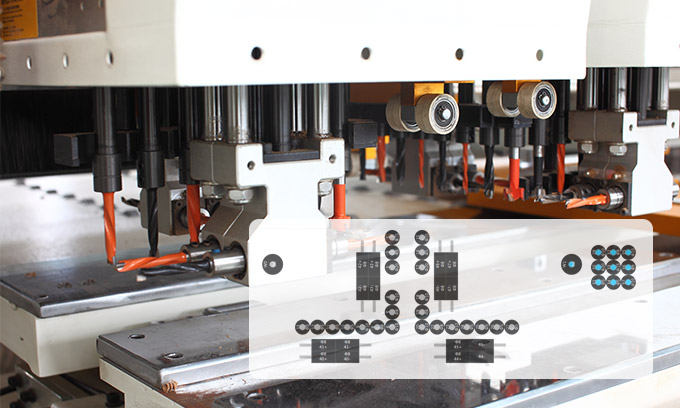

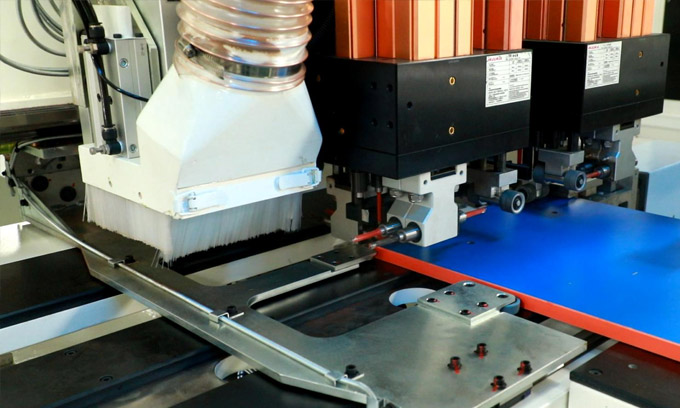

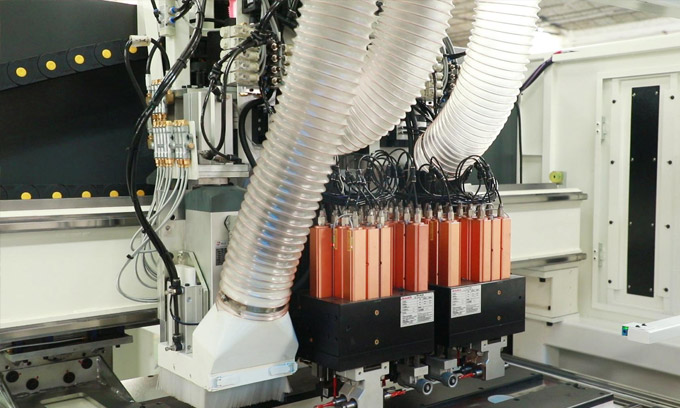

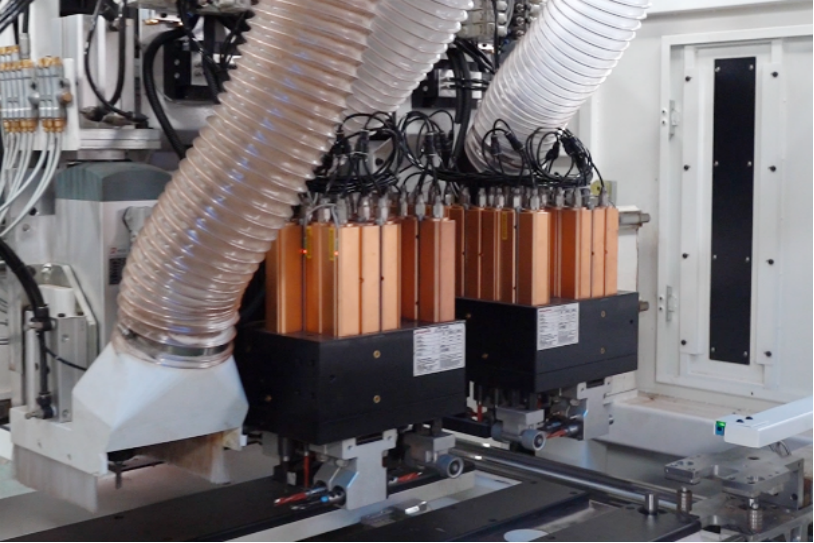

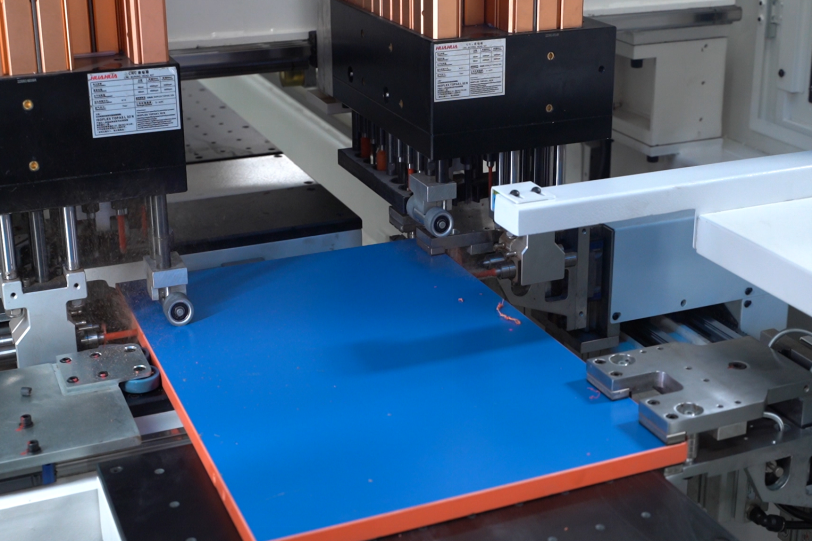

Precision Double Drilling Heads

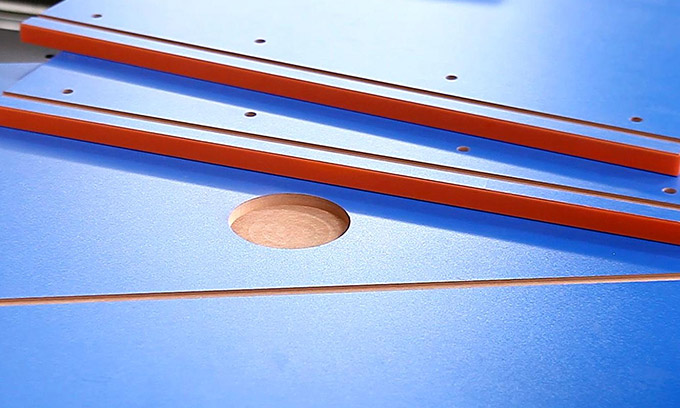

Six-sided machining, drilling, grooving, milling, to meet the needs of different productions.

Drilling bits:

Top: (Vertical 12 + Horizontal 8)*2 groups

Bottom: Vertical 9pcs

Milling spindle: 3.5kw * 2pcs (1 Top + 1 Bottom)

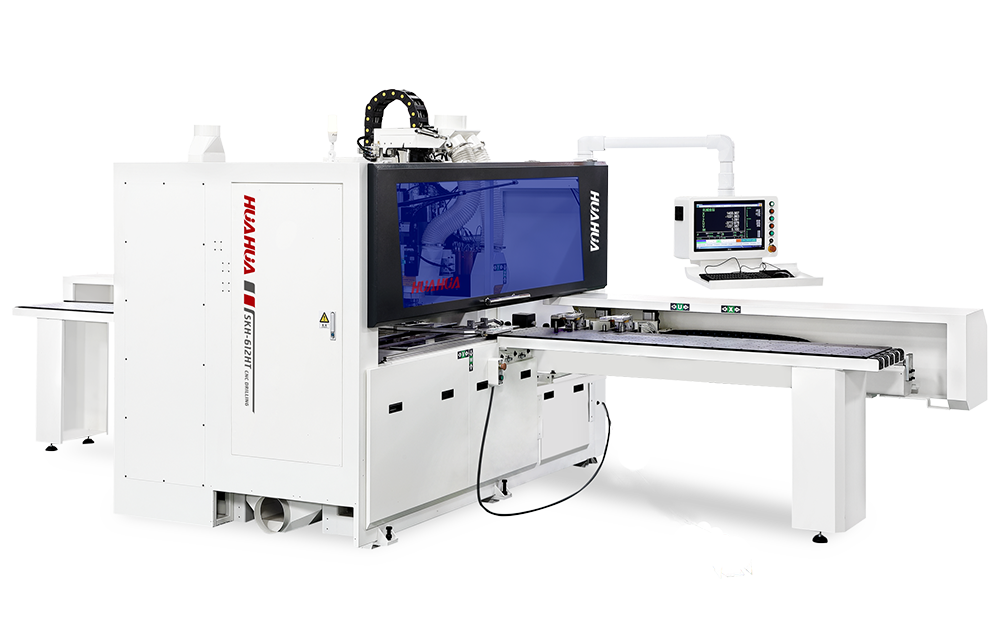

Simultaneous Processing

Two high-precision drilling heads for efficient machining, 20% higher production capacity than a single drilling head machine.

When two holes distance more than 85mm, two drilling heads simultaneous processing

Suit for Bathroom cabinet & kitchen cabinet production

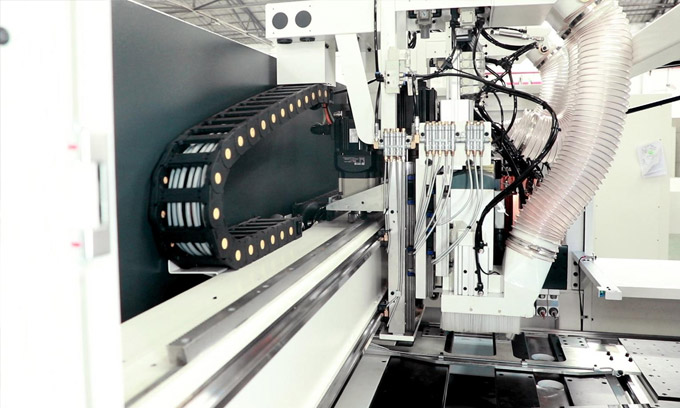

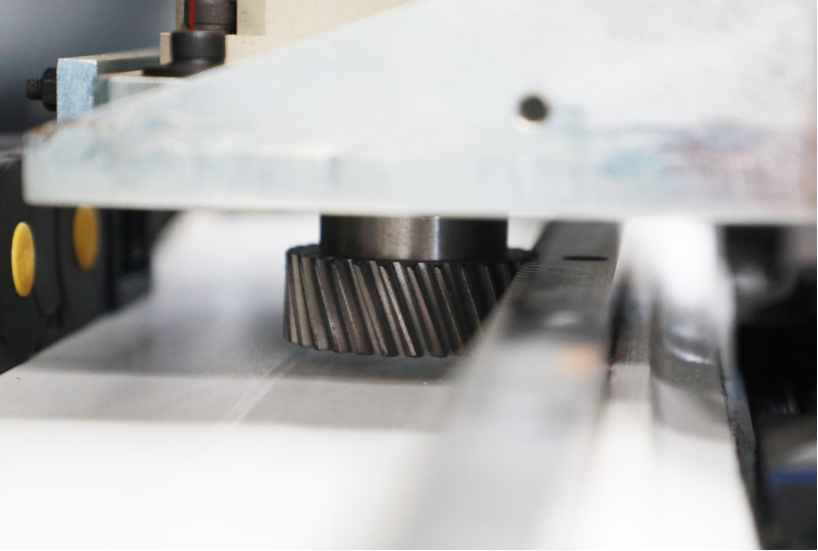

Rack and Pinion Transmission

Both top and bottom drilling heads moving by Pinion and rack transmission, ensure process precision.

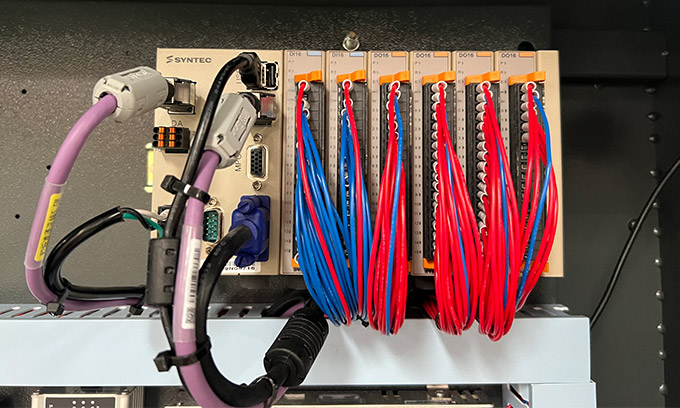

Taiwan Syntec Control System

1.Taiwan Syntec absolute value control, no need for homing, machine can be used immediately once power on.

2. High performance and stability during long service life;

3. Syntec after-sales service branches all over the world.

Taiwan Syntec Servo Motor

1.Taiwan Syntec servo motor control clamp, no need for homing, machine can be used immediately once power on.

2.The clamp moving speed can reach up to 130m/min, fast positioning and drilling

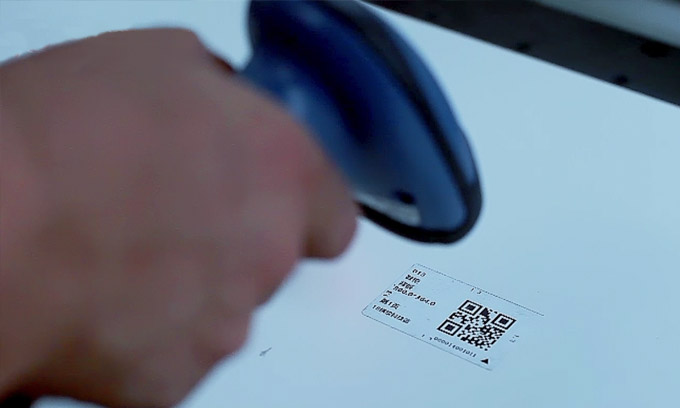

Scan QR Code Loading Processing Files

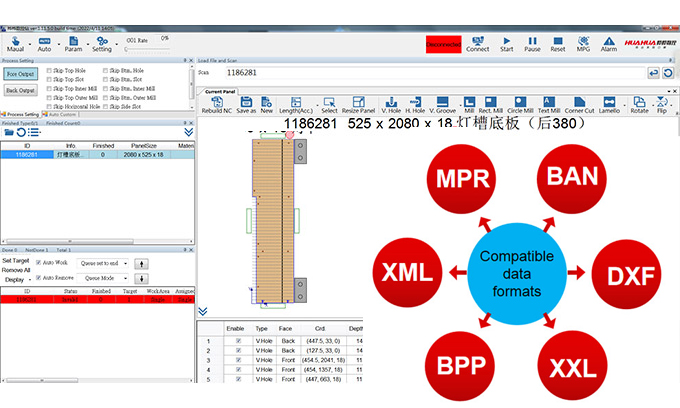

Support barcode / QR code, scan and automatically load processing graphics files like MPR, DXF, BAN, XML etc.,and automatically generate NC program processing

Compatible with Multiple Data Formats

The system shows the users with visual interface, friendly and succinct form, definite meaning of parameter, easy operation

Convenient and efficient opertion

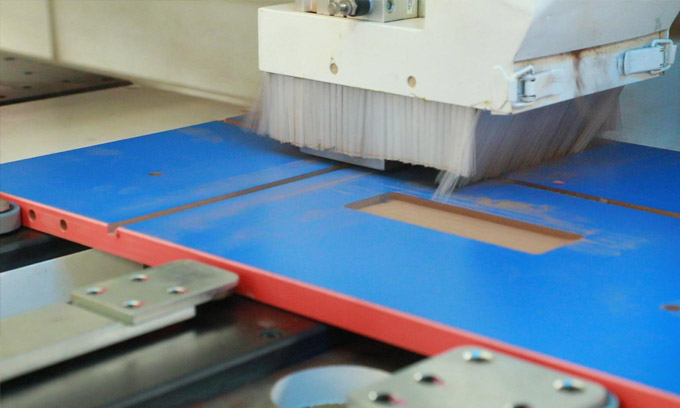

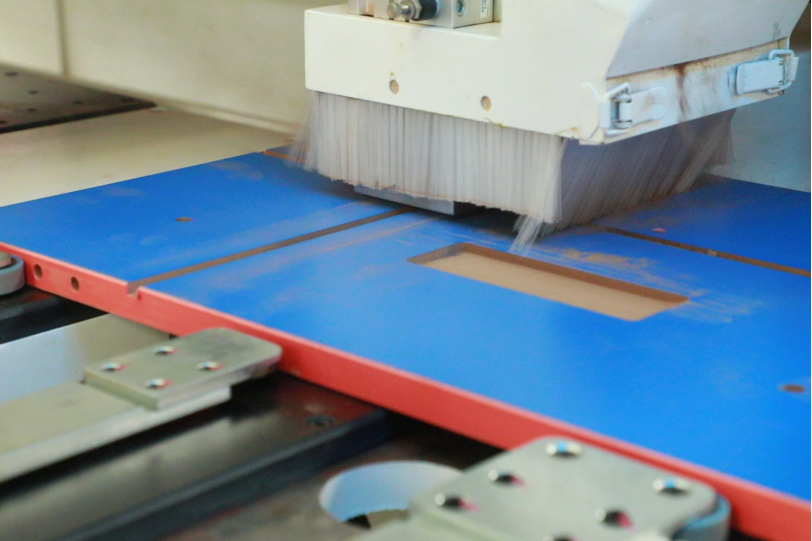

Top Dust Collection

The different processes have different vacuuming ports, combinating blowing and vabuuming, the effect of removing dust is strong, reducing the failure rate and maintenance costs.

Optional

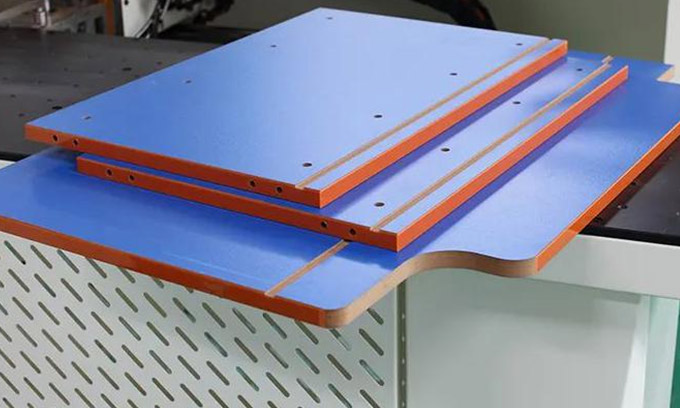

SKH-612NS optional side slot and surface slotting, ATC tool changer and match with side discharge lifting unloading table A variety of unloading options to facilitate automatic connection.

For more options, please consult our sales.

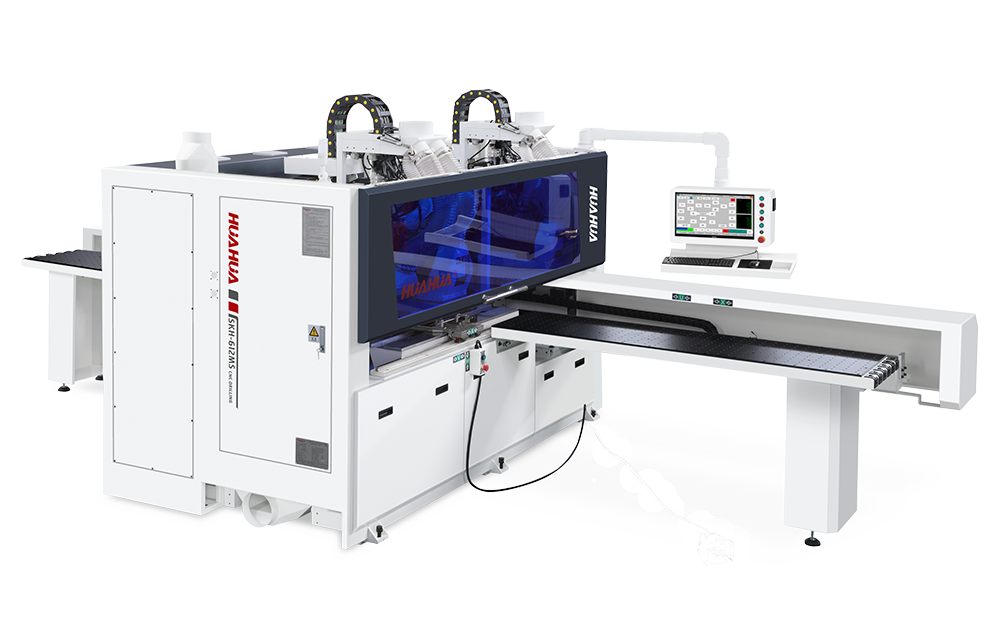

Precision double drill package processing

Two high-precision drilling packages for efficient processing

The production efficiency of six-sided drill and double drill package is increased by more than 20% in one day compared with single drill package.

Powerful

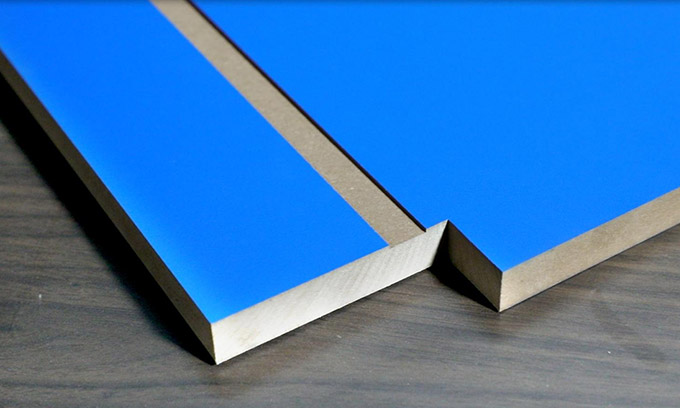

Six-sided processing, drilling, grooving, and milling can meet the production needs of different products. It can process plates with a maximum width of 1200mm and a minimum of 50*250mm.

More stable operation

The frame is machined by precision CNC equipment and annealed, making it durable and not easily deformed, maintaining long-term operational stability and processing accuracy.

High accuracy

Multi-point positioning is more accurate, and six-sided drilling processing is more accurate. The accuracy error can be controlled within 10 wires.

High efficiency and high productivity

Double drill package processing, higher efficiency, six-sided processing, the efficiency can reach 130 meters per minute, can be used as a stand-alone machine, optional in-line processing.

High cost performance

It has good long-term use stability, high accuracy, low failure rate, and low maintenance cost. It is suitable for batch or mixed order production, high efficiency, high productivity, and higher cost performance..

Technical Specifications

| Processing Size Range: |

Min. Width of work-piece | 50mm |

| Max. Width of work-piece | 1200mm | |

| Max. Length of work-piece | 4200mm | |

| Min. Length of work-piece | 250mm | |

| Max. Thickness of work-piece | 48mm | |

| Min. Thickness of work-piece | 10mm | |

| Working Stoke & Max. Position Speed: |

X axis: | 4610mm & 130m/min |

| Y axis: | 1690mm & 85m/min | |

| Z axis: | 130mm & 30m/min | |

| U axis | 4610mm & 130m/min | |

| V axis | 1360mm & 80m/min | |

| Waxis | 110mm & 30m/min | |

| A axis: | 1210mm & 30m/min | |

| Y2 axis: | 1690mm & 85m/min | |

| Z2 axis: | 130mm & 30m/min | |

| TOP Drilling unit: | Vertical drilling bits | 12pcs*2 |

| Horizontal drilling bits | 8pcs*2 | |

| Drilling head motor speed | 2800rmp | |

| Drilling head motor power | 2.2kw | |

| Router Motor power | 3.5kw speed18000rpm | |

| Bottom Drilling unit: | Vertical drilling bits | 9 |

| Horizontal drilling bits | 0 | |

| Drilling head motor speed | 2800rmp | |

| Drilling head motor power | 2.2kw | |

| Router Motor power | 3.5kw speed18000rpm | |

| Other Data: | Working table height | 850mm |

| Total Power | 24.72KW | |

| Voltage | 380V/50Hz | |

| working air pressure | 0.7-0.8Mpa | |

| Vacuum flow | 7200m³/h | |

| Weight | 2520KG | |

| Overall size | 5470*2625*2200mm |

Applications

6 sides drilling, grooving, meet all kinds of furniture production needs.