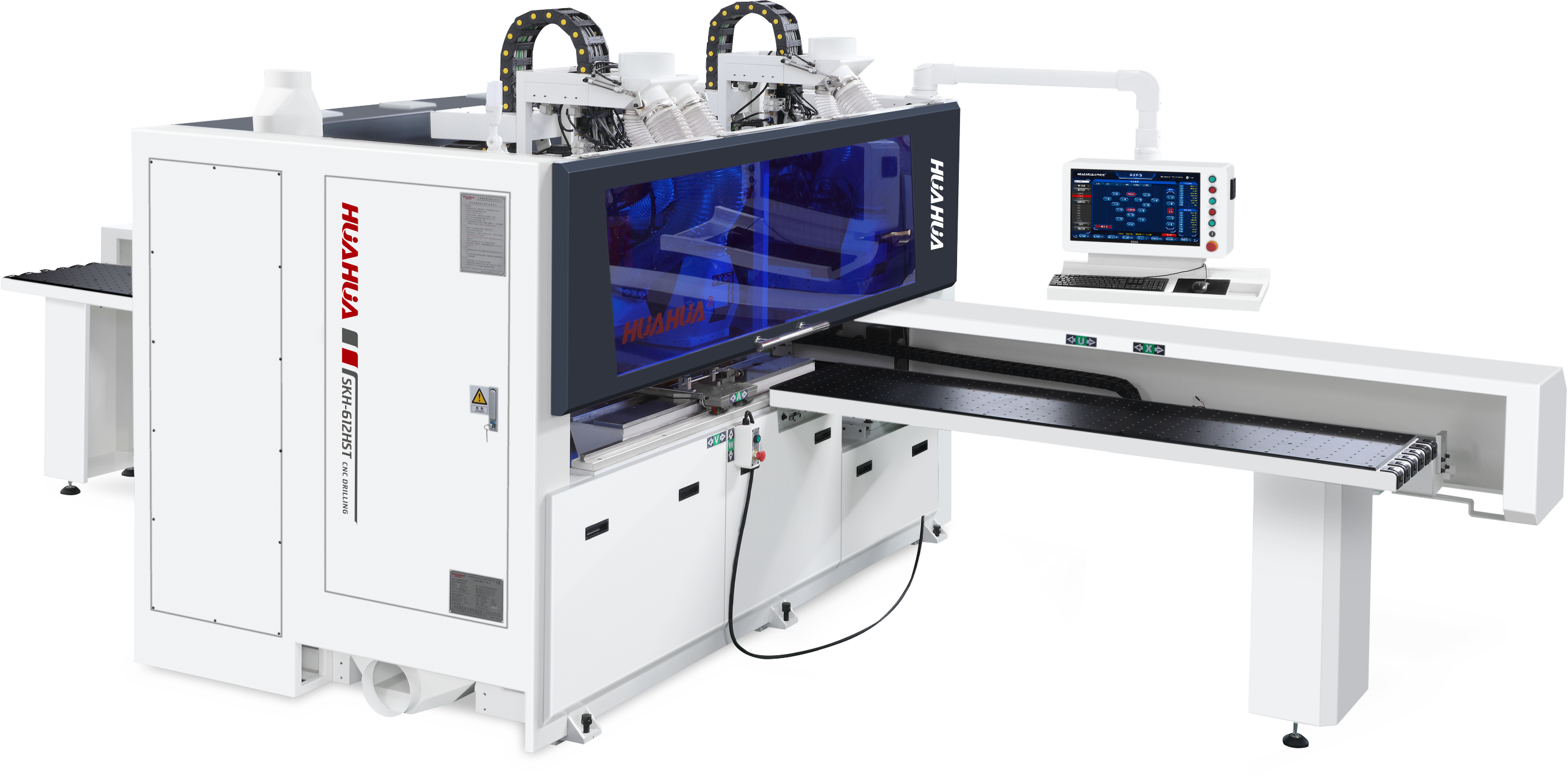

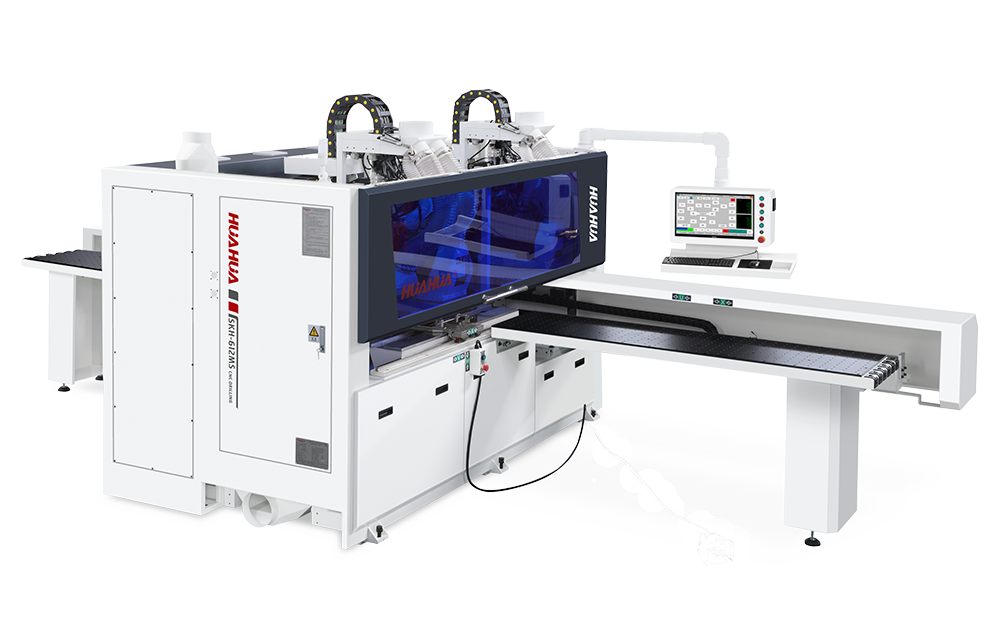

SKH-612HST

SKH-612HST

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

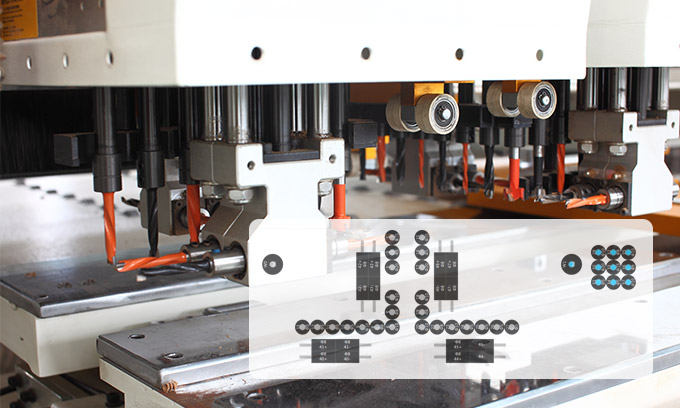

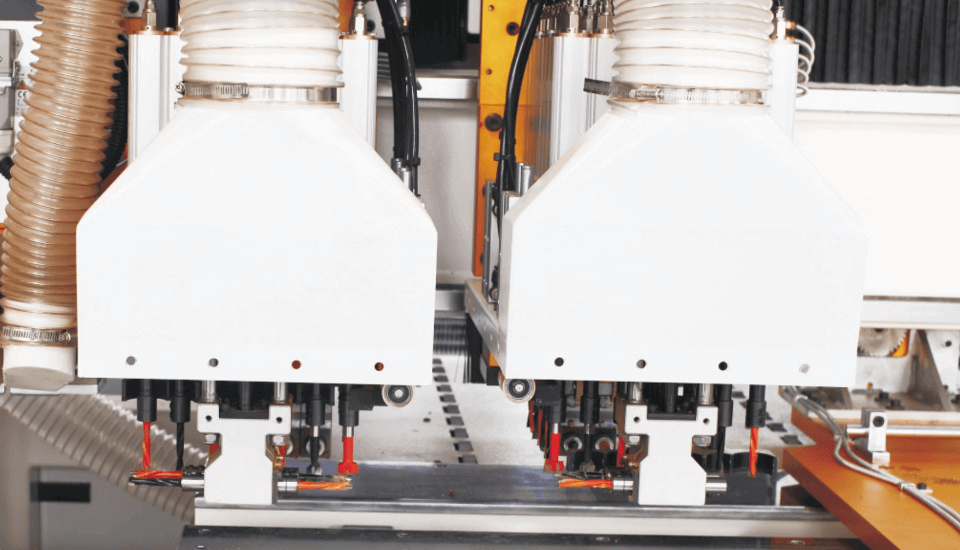

Double Precision Drilling Heads

Using HUAHUA independently developed CNC drilling heads, Manufacturing in accordance with international standards,After three-coordinate detection, the accuracy is guaranteed.

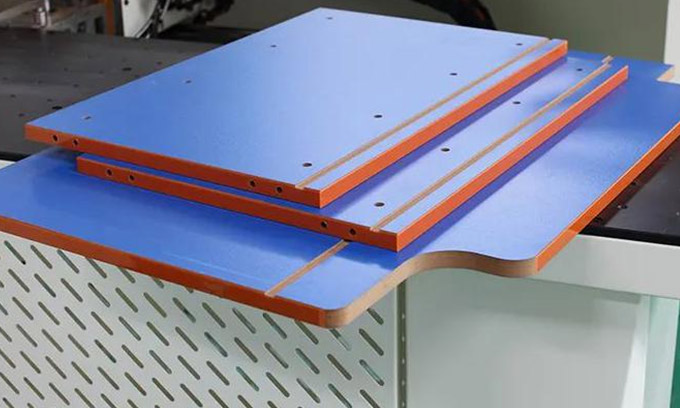

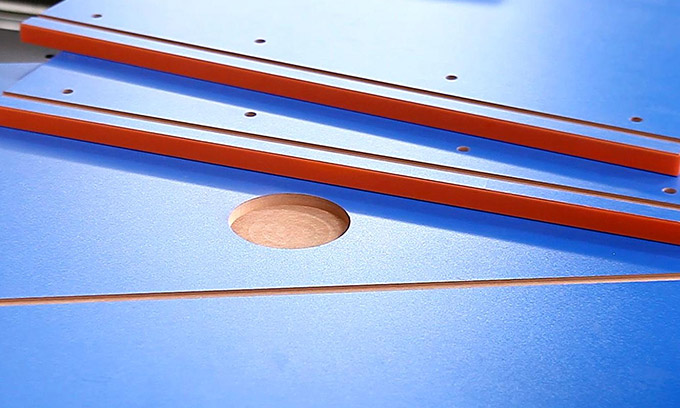

One time processing can complete panel 6-side drilling & 2-side grooving works.

Drilling bits:

Top: (Vertical 12 + Horizontal 8)*2 groups

Bottom: Vertical 9pcs

Milling spindle: 3.5kw * 2pcs (1 Top + 1 Bottom)

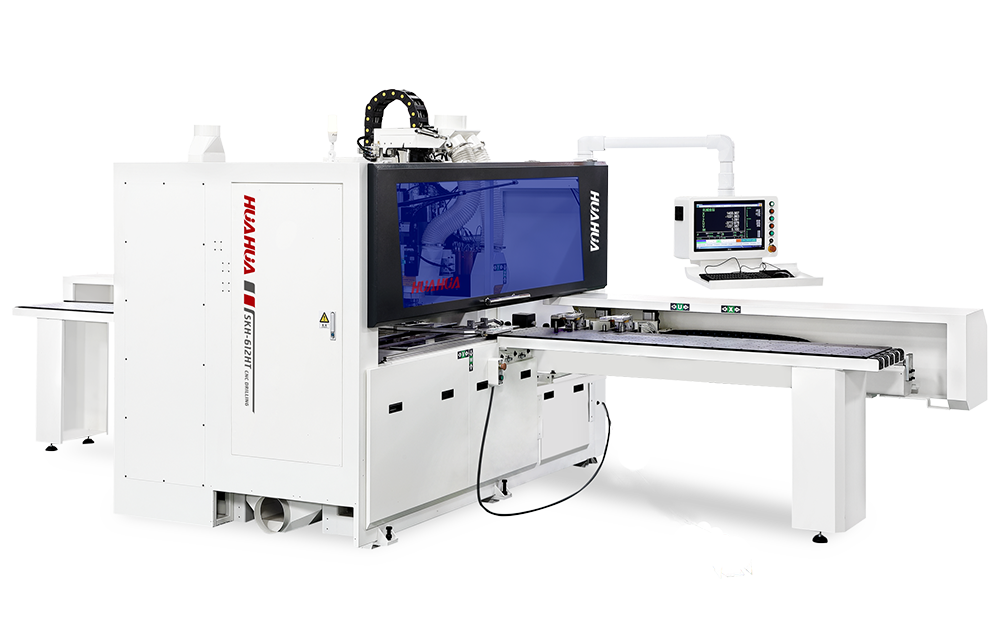

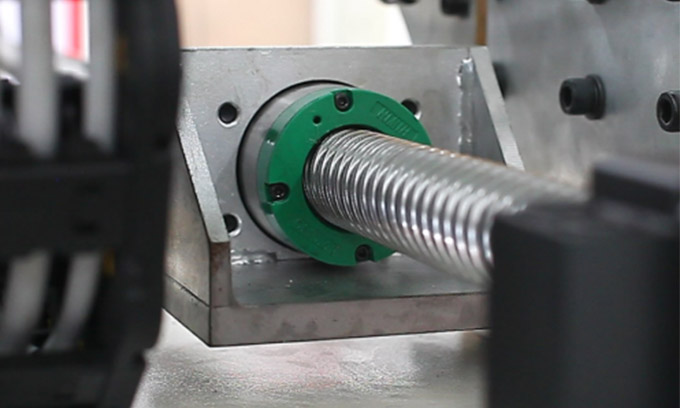

Taiwan HIWIN Ball Screw Drive

Using ball screw drive, the screw drive error is within 0.05-0.1MM, the cumulative error is within ±0.2MM, and the service life of the whole machine is improved.

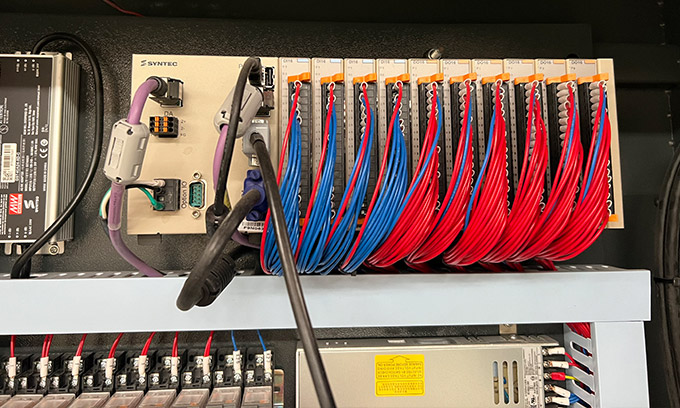

Taiwan Syntec Control System

Taiwan Syntec control system + Taiwan Syntec servo motor

1.Taiwan Syntec absolute value control, no need for homing, machine can be used immediately once power on.

2. High performance and stability during long service life;

Double Drilling Heads Simultaneous Processing

When two holes distance more than 85mm, two drilling heads simultaneous processing

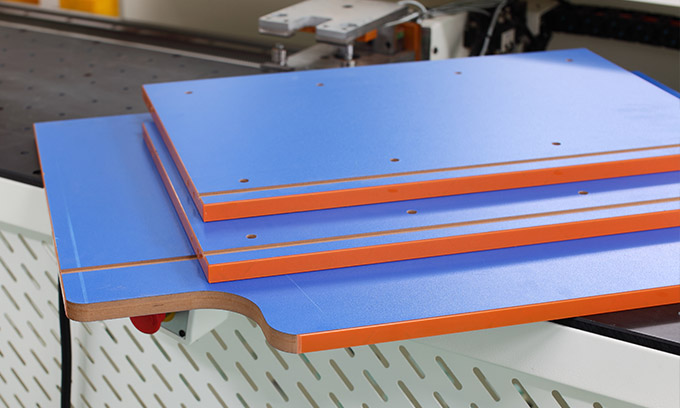

Suit for Bathroom cabinet & kitchen cabinet production

Four tool magazines with automatic tool changing

The straight-line four-tool magazine allows for continuous and efficient processing, which can be used to make horn handles, embedded handles, laminos, and a variety of invisible parts.

Double gripper

Using C-shaped groove double clamping mechanism, according to the computer drilling program,

Automatically control board feeding and positioning to improve drilling accuracy.

The clamping hand will lift up and hang in the air when the clamping plate moves. The plate should be kept at a certain distance above the processing table to avoid damage to the plate surface due to collision between the plate and the table.

*Optional four-clamp handle

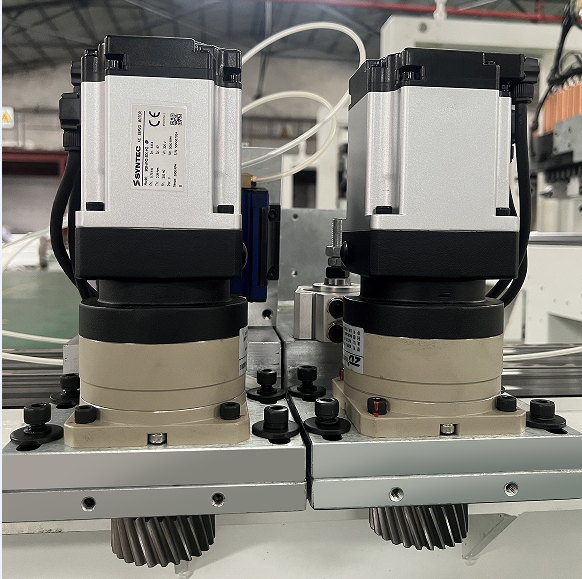

Taiwan Syntec Motor

Servo controlled gripper positioning quickly and accurately.

The gripper speed can reach up to 130m/min.

Flexible discharging

Optional front/rear/side discharging

Combined with the automatic lifting and unloading table, multiple unloading options are convenient.

Automated wiring

Frog leaping technology

Parabolic trajectory reduces idling time and enables fast drilling speed.

Improve efficiency

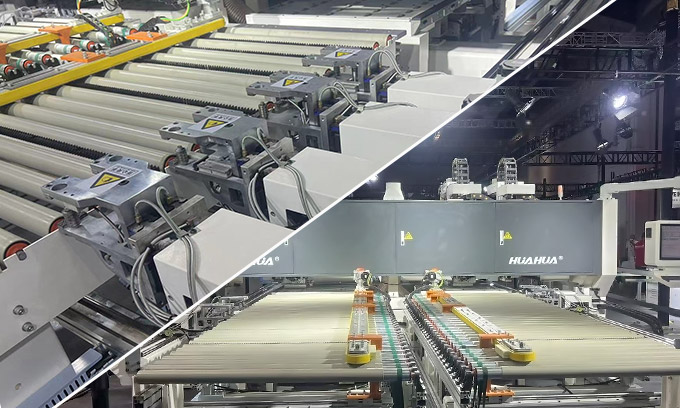

Optional

SKH-612HS can be equipped with front and rear rollers to become a automatic line, and can also be equipped with 4 clamps. For more options, please consult our salesman.

Technical Specifications

| Processing Size Range: |

Min. Width of work-piece | 50mm |

| Max. Width of work-piece | 1200mm | |

| Max. Length of work-piece | 5000mm | |

| Min. Length of work-piece | 250mm | |

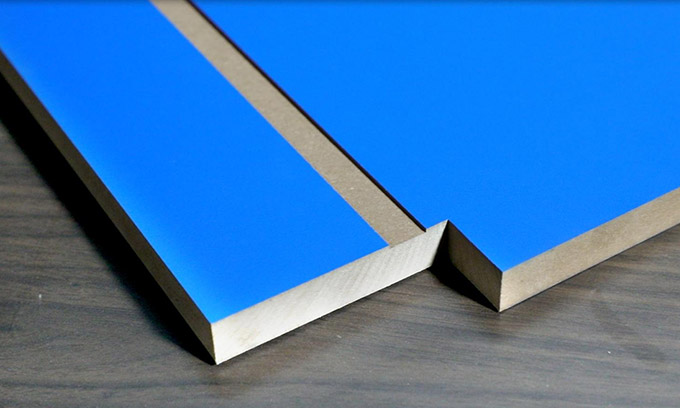

| Max. Thickness of work-piece | 48mm | |

| Min. Thickness of work-piece | 10mm | |

| Working Stoke & Max. Position Speed: |

X axis: | 5410mm & 130m/min |

| Y axis: | 1630mm & 85m/min | |

| Z axis: | 130mm & 30m/min | |

| U axis | 5410mm & 130m/min | |

| V axis | 1340mm & 80m/min | |

| Waxis | 110mm & 30m/min | |

| A axis: | 1195mm & 30m/min | |

| Y2 axis: | 1630mm & 85m/min | |

| Z2 axis: | 130mm & 30m/min | |

| TOP Drilling unit: | Vertical drilling bits | 12pcs*2 |

| Horizontal drilling bits | 8pcs*2 | |

| Drilling head motor speed | 2800rmp | |

| Drilling head motor power | 2.2kw*2 | |

| Router Motor power | 3.5kw speed18000rpm | |

| Bottom Drilling unit: | Vertical drilling bits | 9 |

| Horizontal drilling bits | 0 | |

| Drilling head motor speed | 2800rmp | |

| Drilling head motor power | 2.2kw | |

| Router Motor power | 3.5kw speed18000rpm | |

| Other Data: | Working table height | 960mm |

| Total Power | 24.1KW | |

| Voltage | 220V/380V/415V/ OPTION | |

| working air pressure | 0.7-0.8Mpa | |

| Vacuum flow | 9400m³/h | |

| Weight | 3850KG | |

| Overall size | 6480*2840*2200mm |

Applications

6 sides drilling, grooving, meet all kinds of furniture production needs.