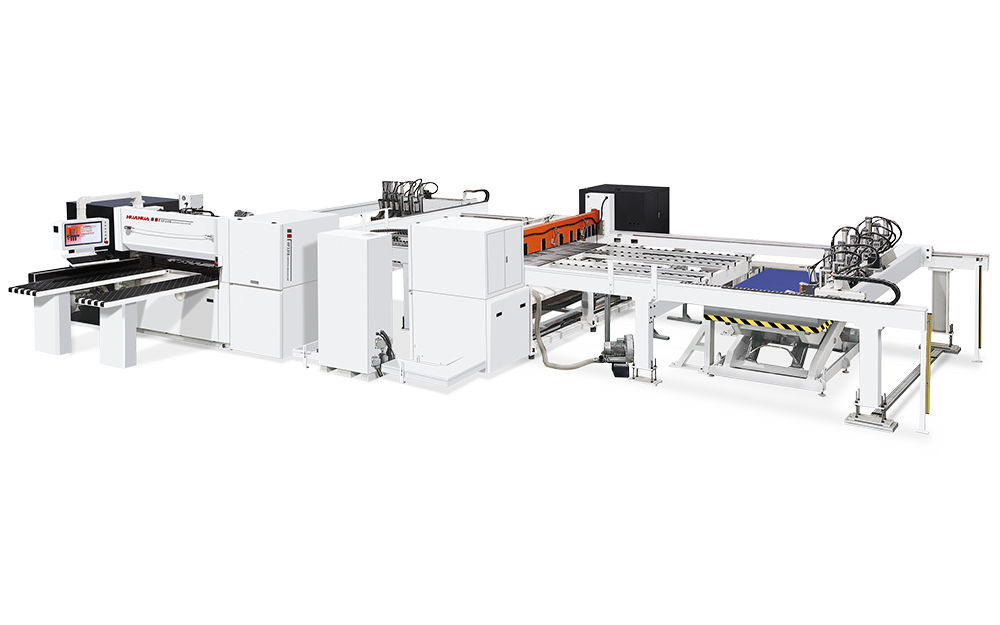

HP3318

HP3318

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

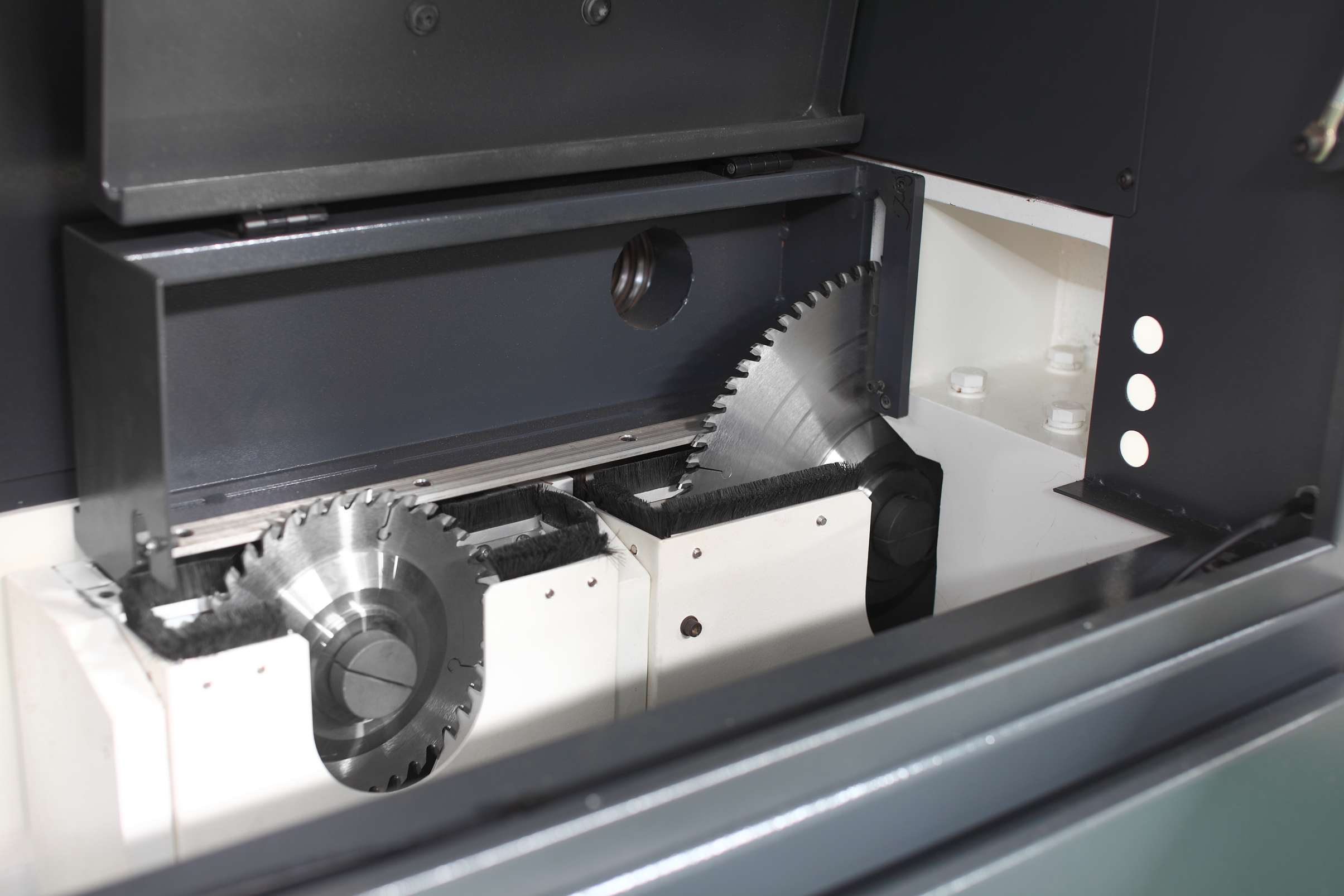

Saw Carriage

Maximum vertical cutting length: 3300mm;

Maximum horizontal cutting length: 1800mm;

High Efficiency

Single pc cutting or multiple pcs cutting, high efficiency.

21" Industrial PC control system

1) Easy operation, safety & reliable.

2) Which has complete operating hints and troubleshooting guide functions.

3) It’s cutting plan can edit manually; can simulate or execute cutting plans.

4) Can compatible with bar code manage software or factory automation software.

Main steel frame

After the welding of the frame is completed, it is placed for one month, and then heat treated,

Eliminate the residual stress generated during the machining process,

Change the crystal structure inside the material,

Enhance the stability of the subject,

Afterwards, it will be treated for 6 months,

Then send to the machining center for precision machining.

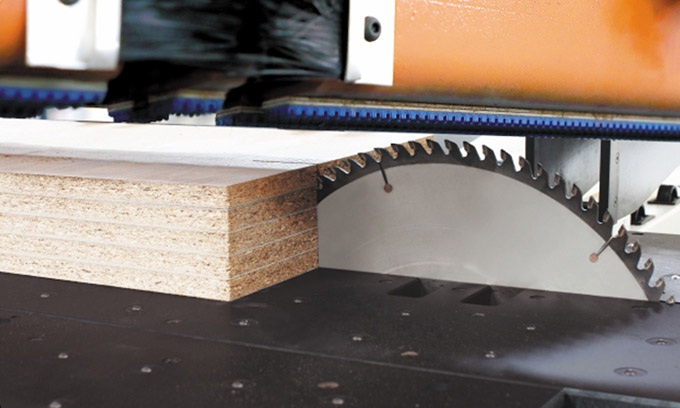

Saw base/drive motor

Saw speed can reach 120m/min

The forward speed of the groove saw is 0-100m/min, the backward speed of the saw base is 0-120m/min, the maximum sawing speed is 0-80m/min, the 2kw saw base drive motor, high-speed panel cutting, stable and efficient.

CPU control motherboard

FX3U Japan Mitsubishi PLC

The third generation micro programmable controller has built-in large-capacity RAM memory up to 64K, built-in the industry’s highest level of high-speed processing 0.065μS/basic command, built-in independent 3-axis 100kHz positioning function. (transistor output type)

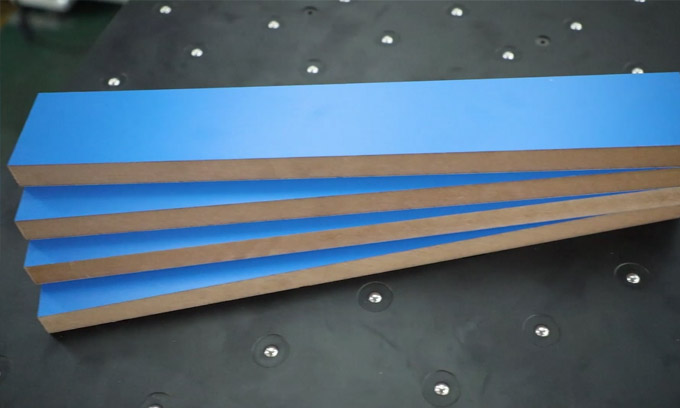

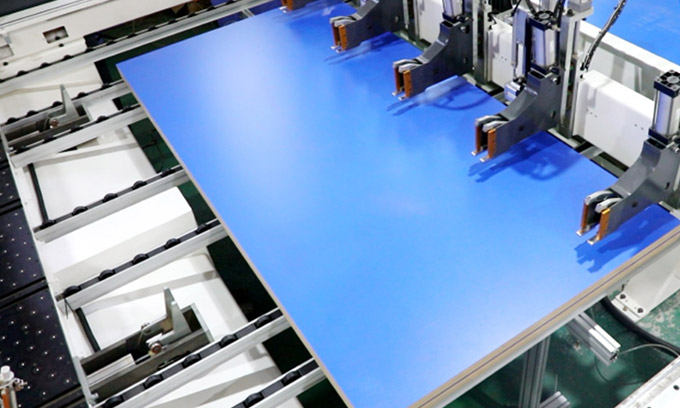

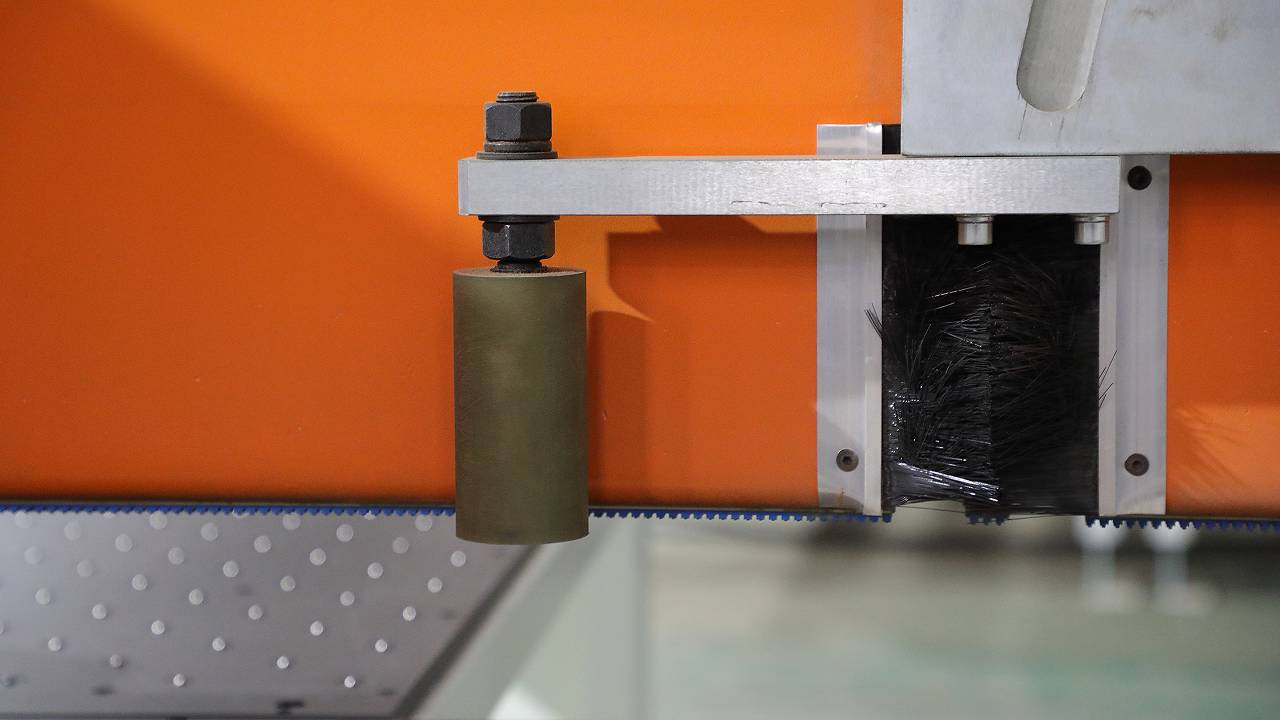

Two-finger clamping structure

It adopts the industry-leading two-finger clamping structure. The plate clamping uses a cylinder, and the material is fed forward through the roller bed surface. The feeding is accurate, ensuring the precision of fixed-size sawing, and will not damage the surface of the workpiece.

Beam pressure device

The pressure beam automatically rises and falls according to the program, which greatly improves equipment safety.

Screw control lifting

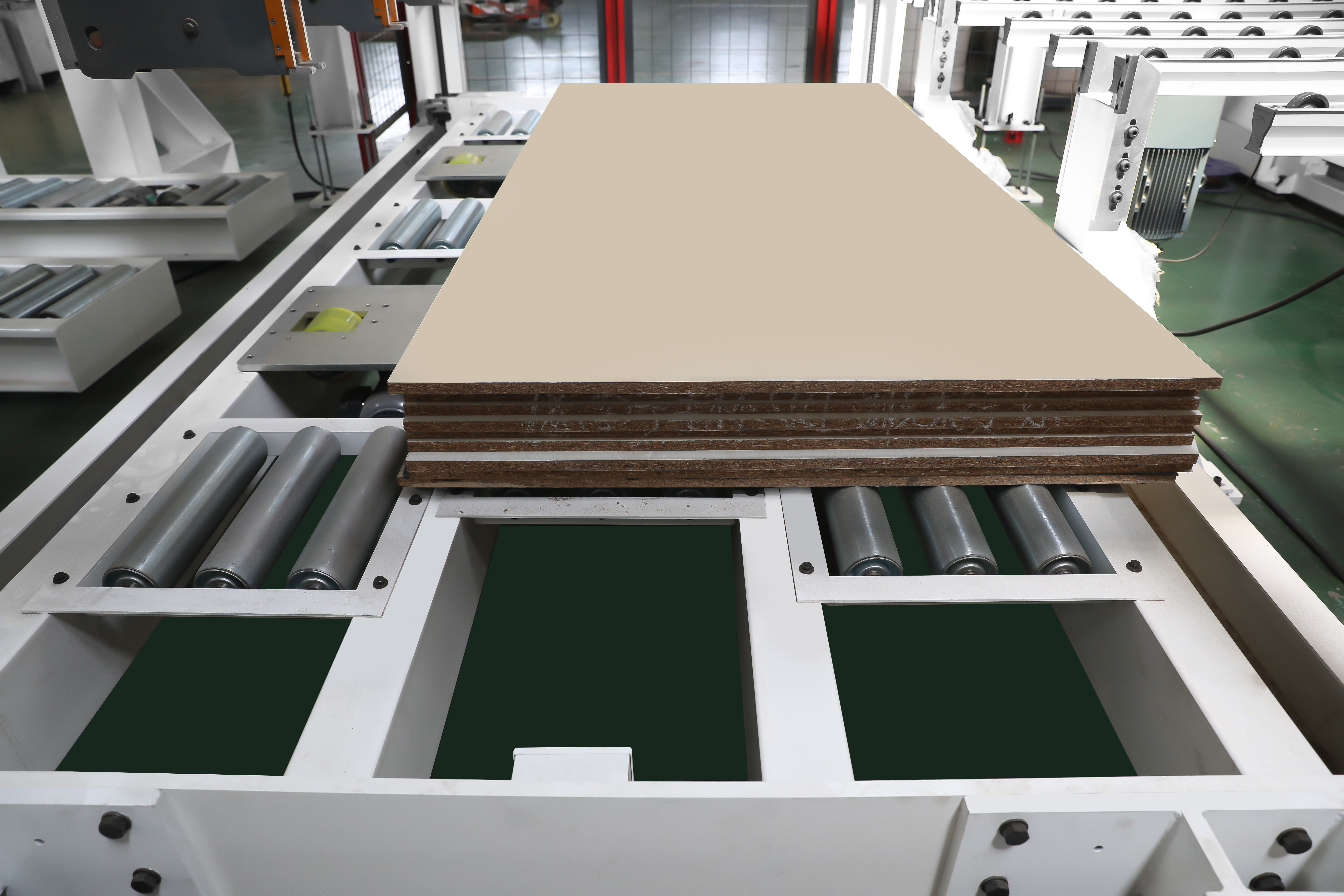

The lifting table uses a screw rod to control the feeding height more accurately, and the brake motor automatic start and stop, more stable lifting.

Automatic rear loading

Precise and stable processing, automatic roller feeding, and automatic rear loading of the lifting table.

Technical Specifications

| Max. cutting length | 3300mm |

| Max. horizontal cutting length | 1800mm |

| Max. cutting thickness | 100mm |

| Main saw blade | Φ380mm(option450mm) |

| Main saw shaft diameter | Φ75mm |

| Main saw shaft rotation speed | 4000rpm |

| Scoring saw blade diameter | Φ200mm |

| Scoring saw shaft diameter | Φ50 |

| Scoring saw shaft rotation speed | 5200rpm |

| Saw carriage forward speed | 0-100m/min |

| Saw carriage backward speed | 0-120m/min |

| Main saw motor power | 18.5kw*2 |

| scoring saw motor power | 2.2kw*2 |

| Saw carrier driving motor power | 2kw*2 ( AC sevro ) |

| Automatic feeding motor | 2kw*2 ( AC sevro ) |

| High-pressure blower motor | 3kw*2+2.2kw |

| Side aligner motor | 0.25kw |

| Lifting platform motor | 2kw |

| Conveyor motor | 0.75kw*2 |

| Total power | 61.35kw |

| Automatic Feeding speed | 85m/min |

| Air pressure | 5-7kg/cm² |

| Worktable height | 960mm |

| Net weight | 14300kg |

| Machine size | 8000*11600*2200mm |

| Air floating table quantity | 2 |

Applications

Industrial-grade cnc panel caw, precise cutting, high efficiency and labor-saving.