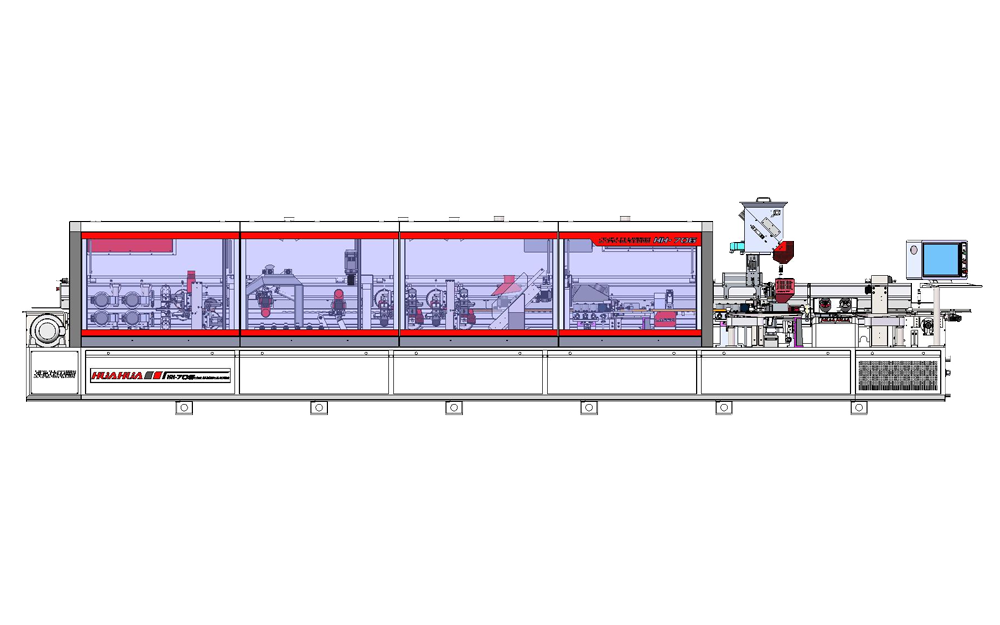

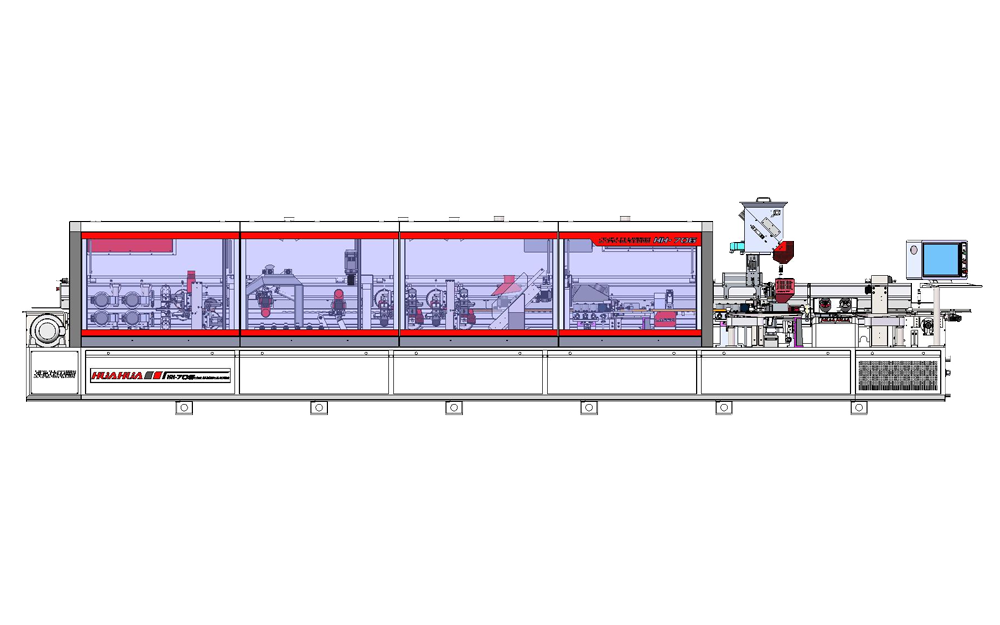

HH-706RLK-Laser300

HH-706RLK-Laser300

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

21.5 inch large computer screen

The human-computer interaction is simpler, the large screen has a large field of view, the interface is clearer, and it is easy to operate and use

The standard is English and Chinese language systems, and minor languages can also be customized according to customer needs

It can remotely control the computer, monitor the working status of the computer, and the after-sales processing is more convenient and faster

Automatic oiling device

According to the use time of machine working,automatic oiling maintenance.

Automatically give oiling lubricating maintenance to guide rail,ensure long-term operation stability and smooth processing,prolong the use life of the machine

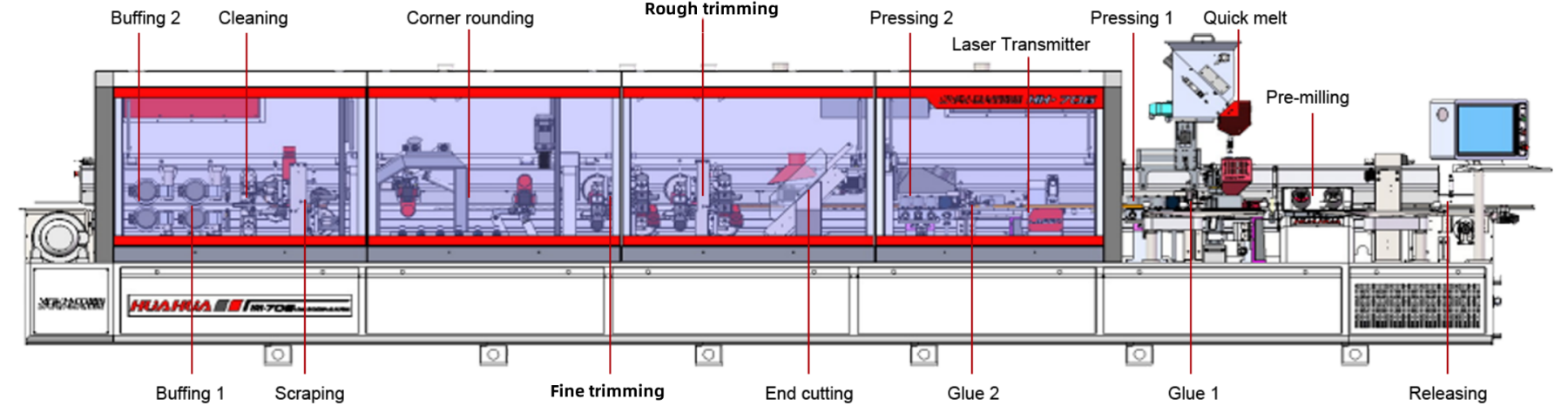

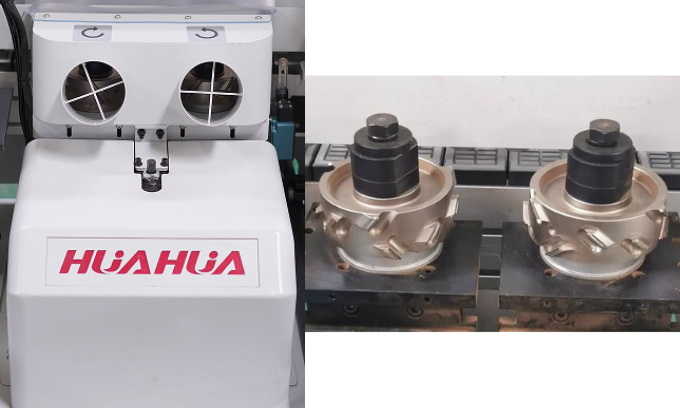

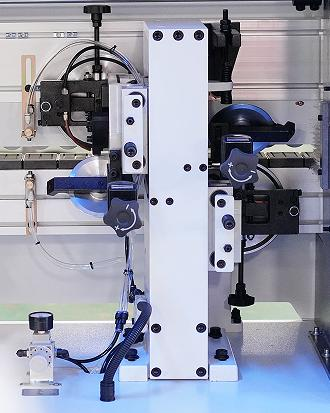

Pre-milling Unit

Trimming the edge of the panel after cutting

Equipped with a 2.2KW high-power motor, it is composed of two milling tools at the front and rear. The maximum pre-milling height is 40mm (65mm is optional).

Milling the corrugated of the surface of the board makes the edge banding and the board more tightly bonded, and the integrity and aesthetics are better.

Quick sol +PUR glue pot

PUR glue pot with a quick melt glue device,only 15 min to sol work

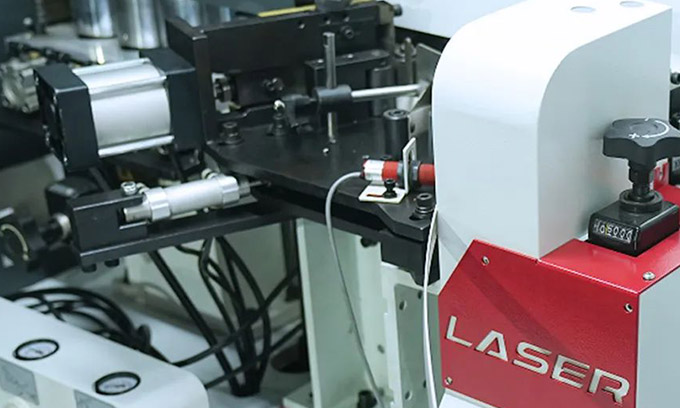

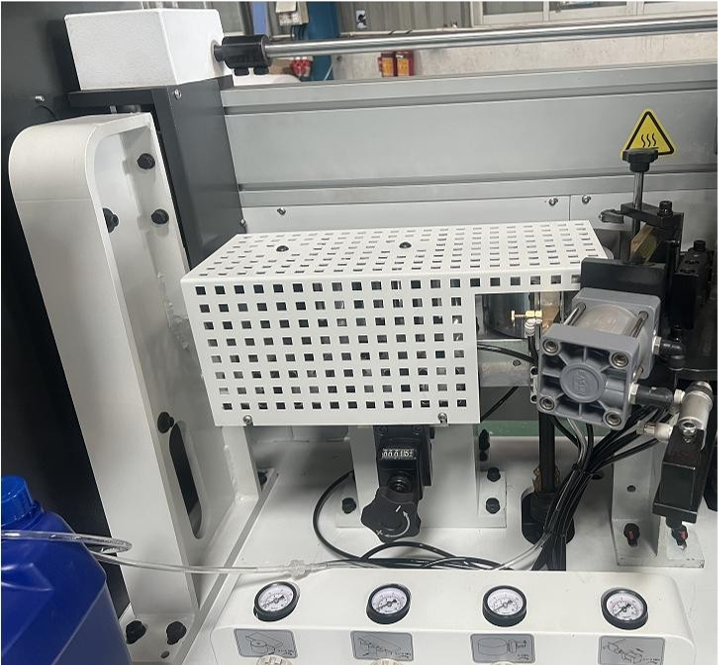

Laser Transmitter

The edge band used is pre-coated with glue and activated by laser, so there is no need to replace the glue and save the time of sol.

Multi-purpose

Laser edge sealing/EVA/PUR device and fast sol are perfectly matched with one-key switching, flexible and convenient operation, multi-purpose.

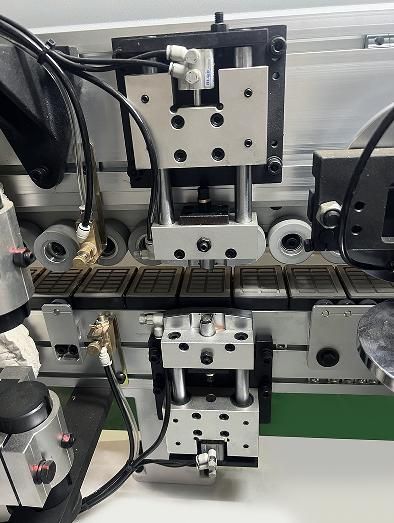

Pressing unit with scraping cutter

Four strong press wheel with scraping cutter,automatically clean the residual glue,make the edge banding surface more beautiful.stick with edge banding tape more tightly,less glue line.

Corner rounding unit

The left and right movable profiling rounding device of the profiling wheel is used to mill the 4 corners of the edge banding tape bonded to the panel into an R arc shape, and the 4 corners of the edge banding of the panel are smoother and more beautiful

Scraping unit

Trim the wavy knife marks on the edge banding so that the size of the R angle is the same as that of the fine trimming R angle, making the upper and lower parts of the board more smooth and tidy

Option Flat Scraping

Remove the remaining glue extruded from the joints of the upper and lower planes of the edge banding glued on the board, so that it is not easy to stick to the buffing wheel and reduce the frequency of buffing wheel replacement

Independent lifting of the pressure beam

The pressing unit, aligning unit and tracking unit all use independent lifting to prevent the panel from shaking and shifting, making it tighter and more stable, with precise edge banding

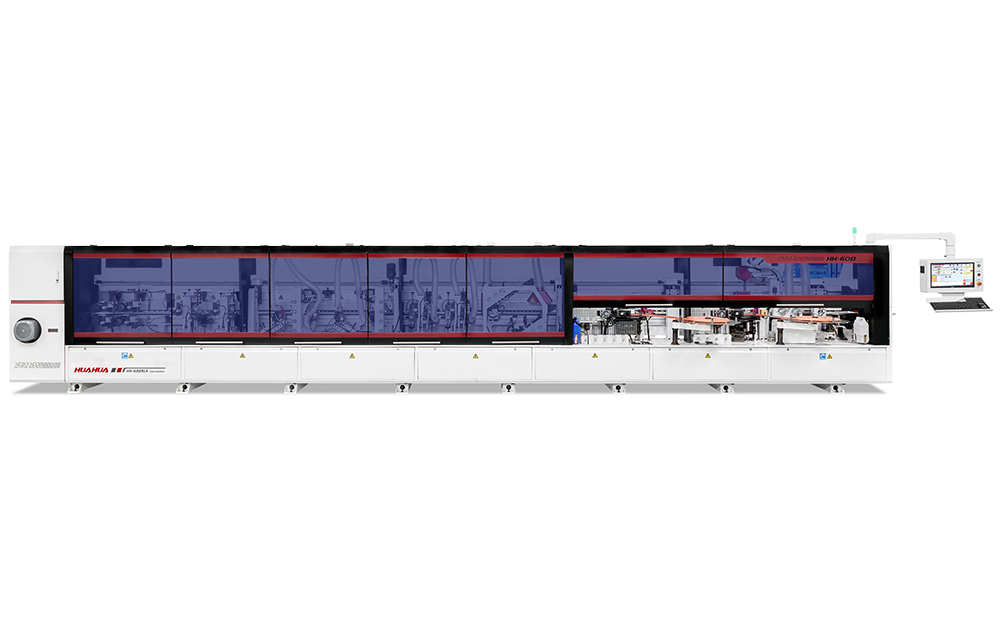

Technical Specifications

| Min. Panel size | ≥120mm | Feed rate | 15-18-20m/min (pur)≤23m/min(Laser) |

| Min. Panel width | ≥120mm | Total power | 33kw |

| Panel thickness | 10-60mm(pur)10~35mm(laser) | Working pressure | 0.65mpa |

| Edge width | 13-63mm | Size | 11700*1100*1950mm |

| Edge thickness | 0.4-3.0mm 0.8-3mm(laser) | Weight | 2700kg |

Applications

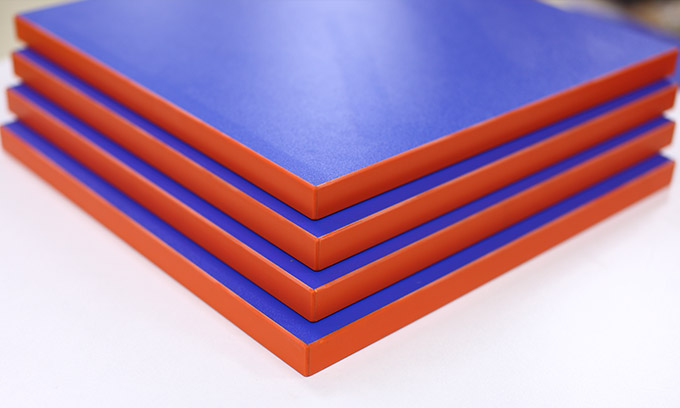

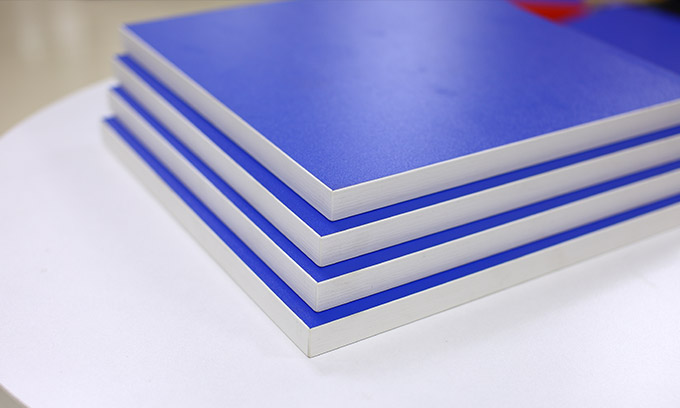

The laser edge band comes with pre-coated glue, the laser temperature is as high as 400-500°C, the edge band is bonded to achieve zero release, no glue lines, no gaps, moisture-proof, high temperature resistance, strong force, glue-free, and high efficiency