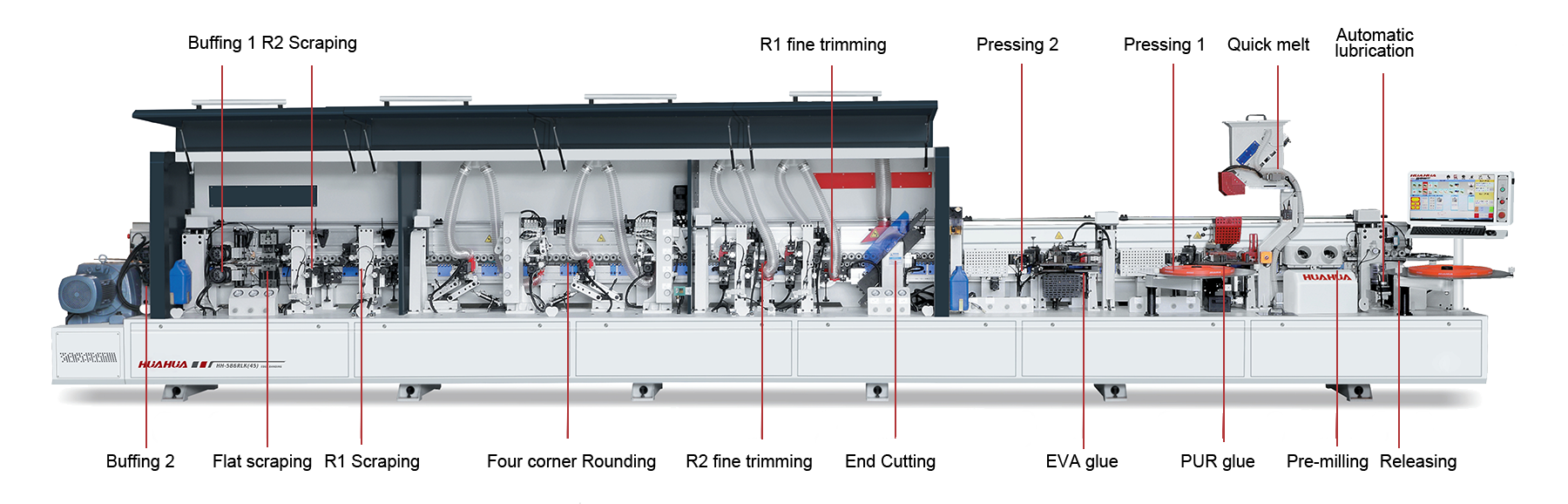

HH-586RLK(45)

HH-586RLK(45)

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

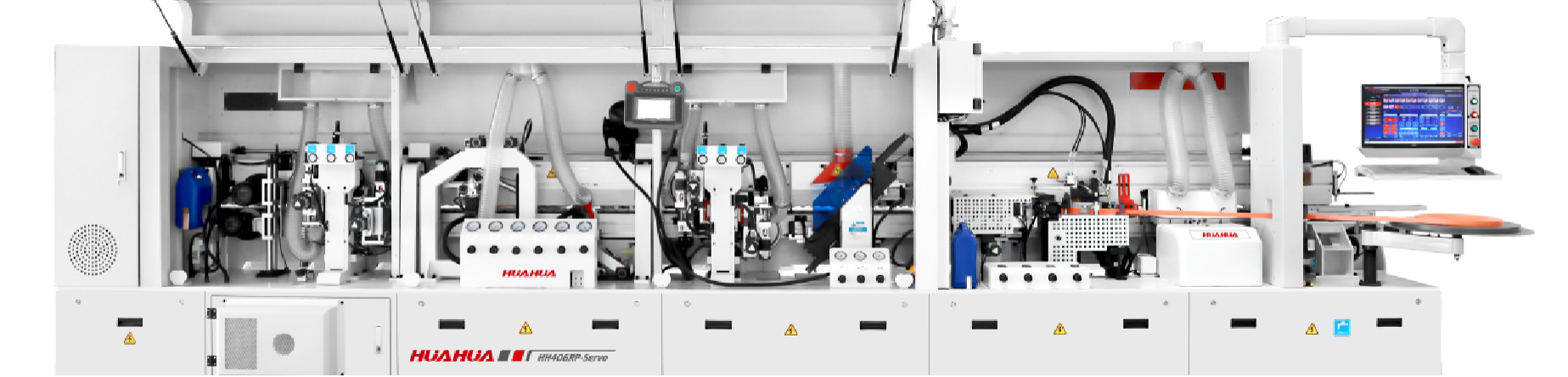

21.5 inch large computer screen

The human-computer interaction is simpler, the large screen has a large field of view, the interface is clearer, and it is easy to operate and use

The standard is English and Chinese language systems, and minor languages can also be customized according to customer needs

It can remotely control the computer, monitor the working status of the computer, and the after-sales processing is more convenient and faster

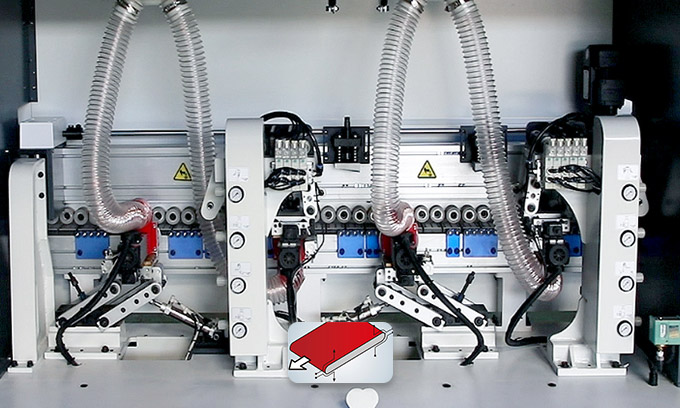

Narrow panel Auxiliary Feeder

Small panel auxiliary feeding device, can seal the narrow side

Minimum size:

40*300mm (when sealing the long side)

45*200mm (when sealing the narrow side)

Large panel auxiliary wheel + narrow side support wheel

Multiple sets of auxiliary wheels can avoid too much shaking when sealing large or long boards

Narrow edge support wheels make the edge banding more accurate and the end edge banding is more stable

Automatic Oil Filling System

According to the use time of the equipment and the frequency of edge banding, the guide rail chain is automatically lubricated to ensure long-term operation stability and smooth processing, and prolong the service life of the machine

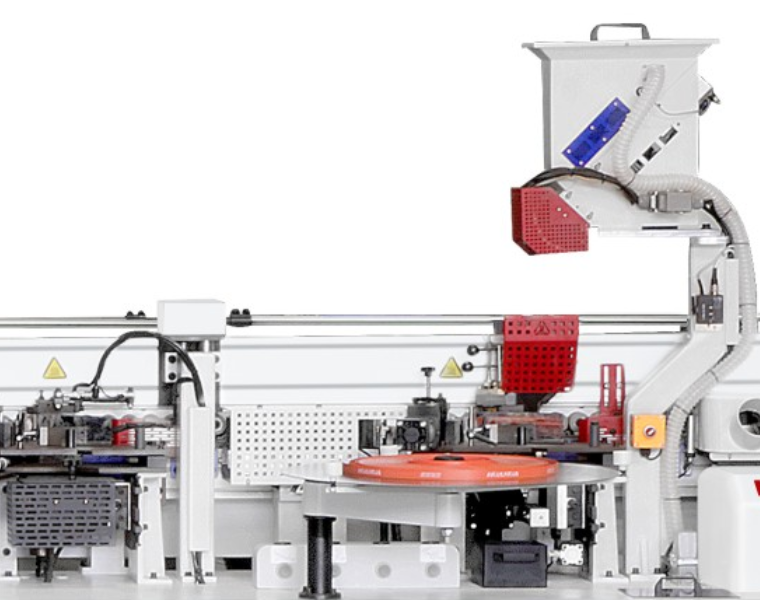

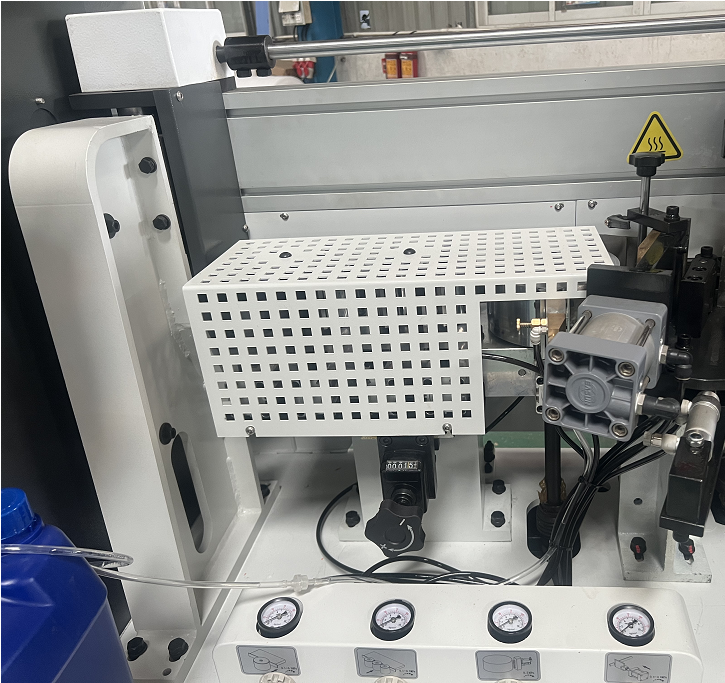

Double glue pot and Quick hot melt Device with automatic glue suction device

From the picture, you can see that there are two glue pots, one PUR glue pot (upper glue pot), one EVA glue pot (lower glue pot), and Quick hot melt Device with automatic glue suction device

The advantage of the double glue pot is that according to different colors of panels and different colors of edge banding, you can choose different colors of glue to solve the problem of glue lines

Quick hot melt Device with automatic glue suction device, It only takes 15 minutes to start working at the fastest, and there is no need to wait for the glue to melt during mass production. Avoid the trouble of manual gluing, work uninterruptedly, and avoid dry burning of the glue pot. automatic glue suction device , no need work add the glue all the time with big Glue storage tank

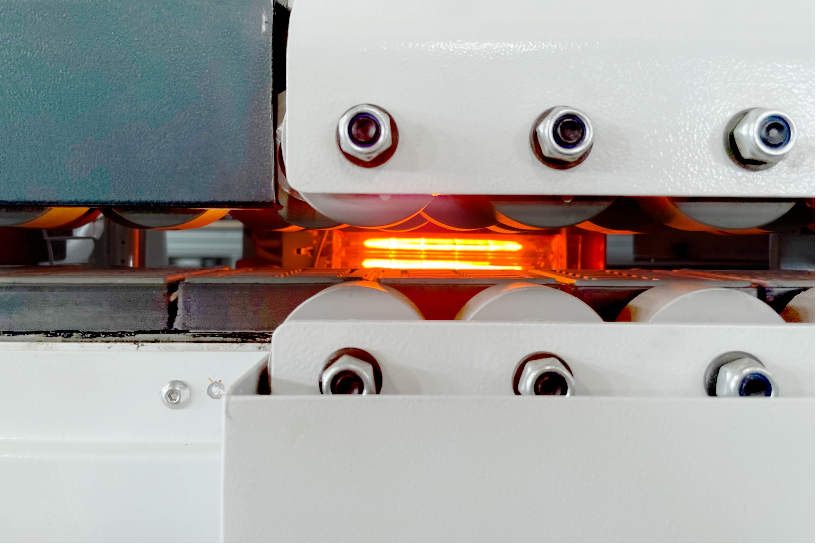

Double Bake Light

Bake Light -preheating, avoid degumming

After the baking lamp preheats the edge of the board, the glue is applied to seal the edge more tightly, and the edge band is pasted more firmly, which can avoid the problem of degumming caused by large temperature differences

Pressing wheel: 4 pcs strong pressing wheels and 1 pcs rubber wheel

4 pcs powerful pressure wheels with 1 pcs rubber wheel, the diameter of the increased pressure wheel is 150mm

The built-in scraper sprays the remaining glue, and the rubber wheel has better coverage and a tighter fit.

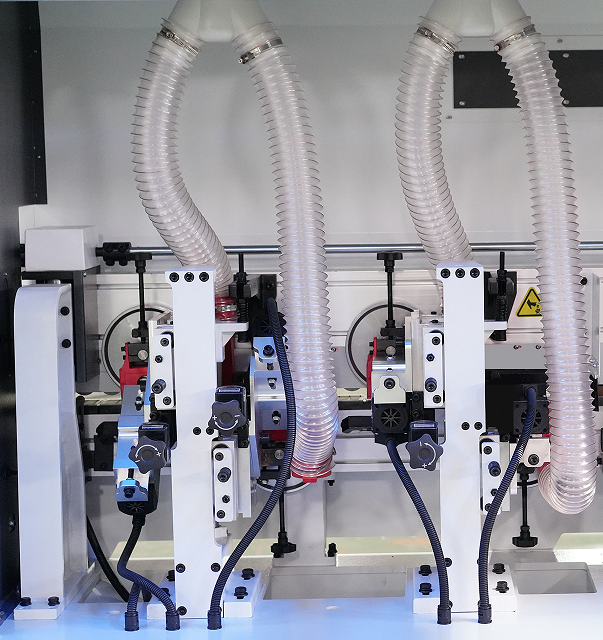

Double fine trimming

The edge is trimmed by the double fine trimming device, which meets the automatic switching of two edge banding belts, saving time and effort, and more effectively improving the edge banding effect

High-speed four-corner rounding

One corner corresponds to a group of devices, easy to adjust, good stability

The compact tracking profile meets the needs of tracking and trimming of long and narrow sides 40x300mm

Independent lifting of the pressure beam

The pressing unit, aligning unit and tracking unit all use independent lifting to prevent the panel from shaking and shifting, making it tighter and more stable, with precise edge banding

Technical Specifications

| Min. narrow short side | 45*200mm |

| Min. narrow long side | 40*300mm |

| Panel thickness | 10-60mm |

| Tape width | 13-63mm |

| Tape thickness | 0.4-3.0mm |

| Feed rate | 18-20-23m/min |

| Total power | 30.5kw |

| Working | 0.65mpa |

| Size | 9763*1000*1900mm |

| Weight | 3100kg |

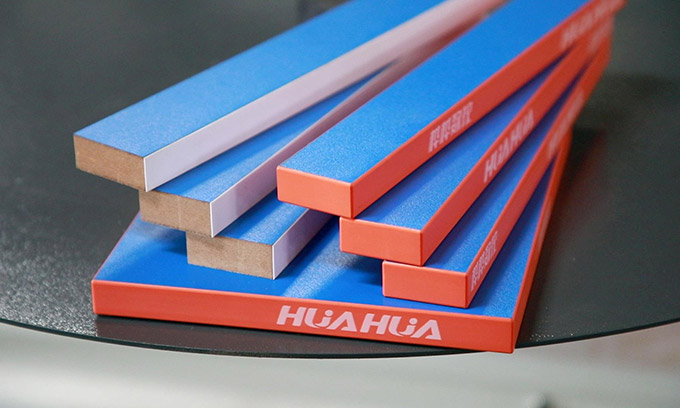

Applications

Narrow edges can also achieve perfect edge banding,Automatic edge banding machine, meet various edge banding needs, the necessary machine for furniture, saving time, labor cost.