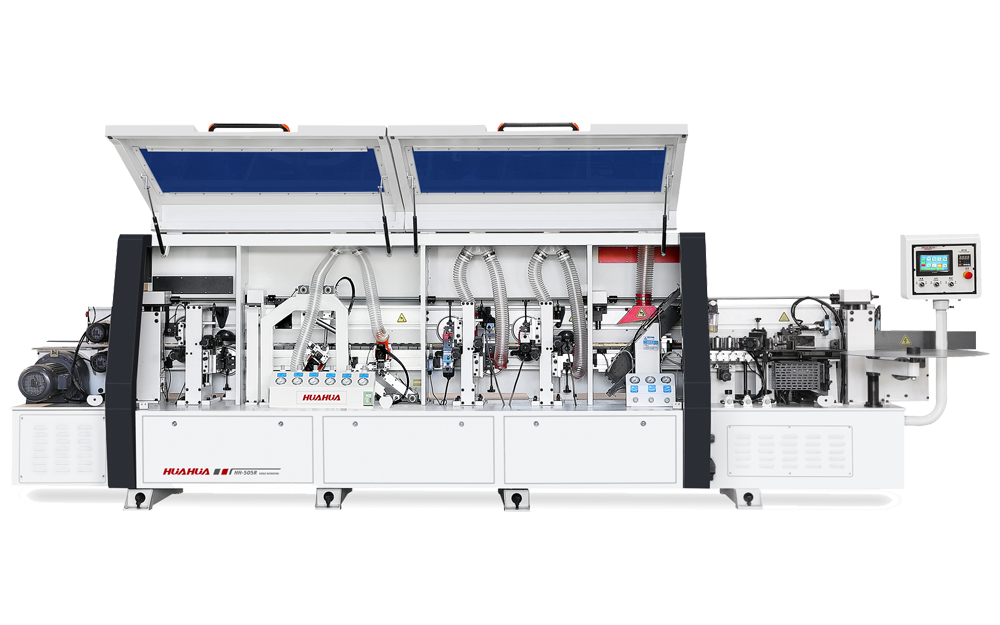

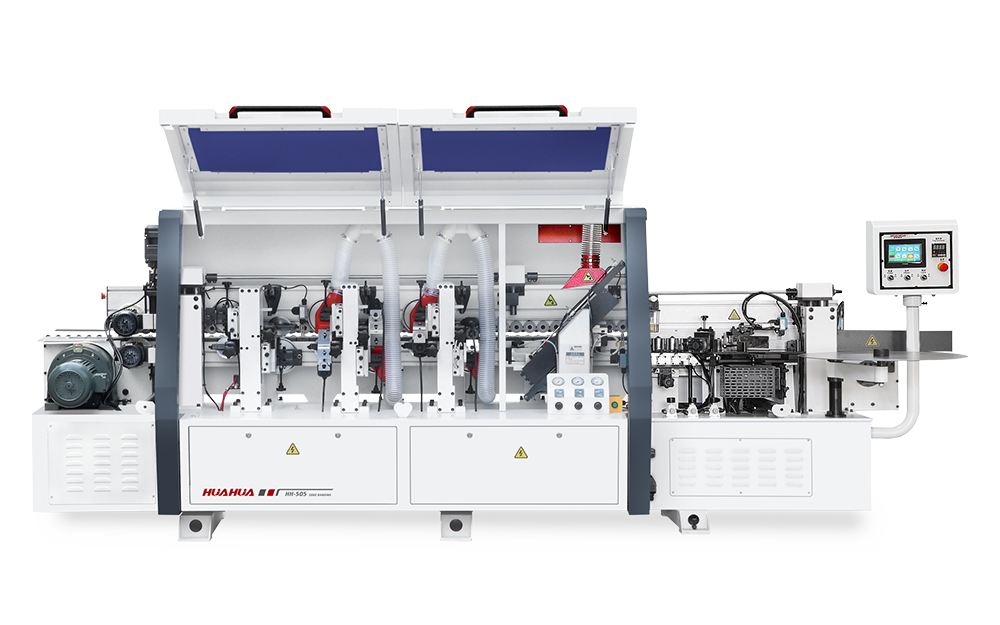

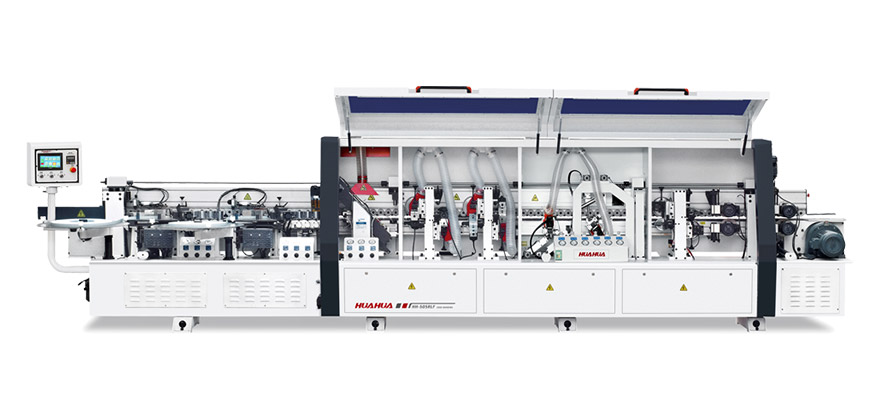

HH-505RLF

HH-505RLF

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

Reverse working edge banding machine

The biggest highlight of this machine is the reverse work. The design is mainly customized according to the customer’s plant placement requirements and the operator’s working direction to make it more convenient.

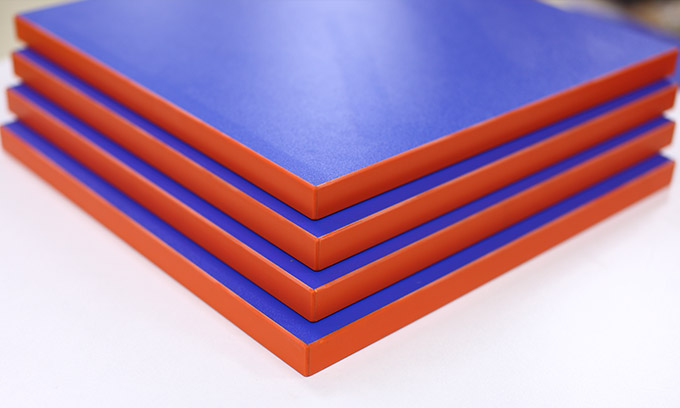

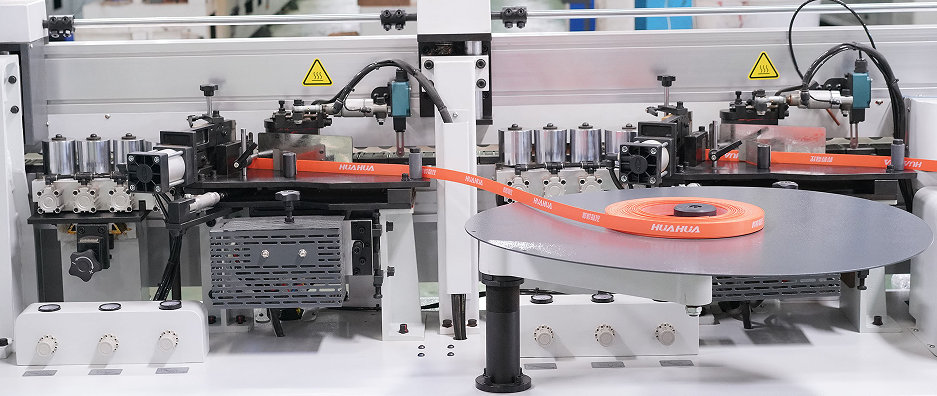

Double Glue Pot

The advantage of the double-glue pot is that it can choose different colors of glue according to different colors of panels and different colors of edge banding to solve the problem of glue lines.

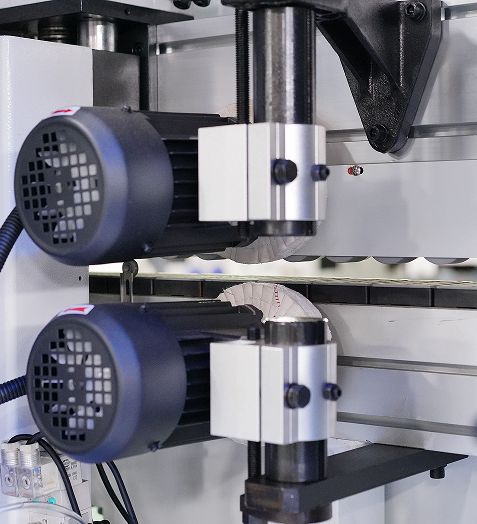

End Cutting Unit

Through the precise linear guide rail movement, the automatic tracking of the profile and the fast cutting structure of the high-frequency high-speed motor are used to trim the protruding edge banding strips at the front end of the plate and the protruding edge banding strips at the rear end of the plate.

Make it flush with the front and back ends of the sheet to ensure that the cut surface is flat and smooth.

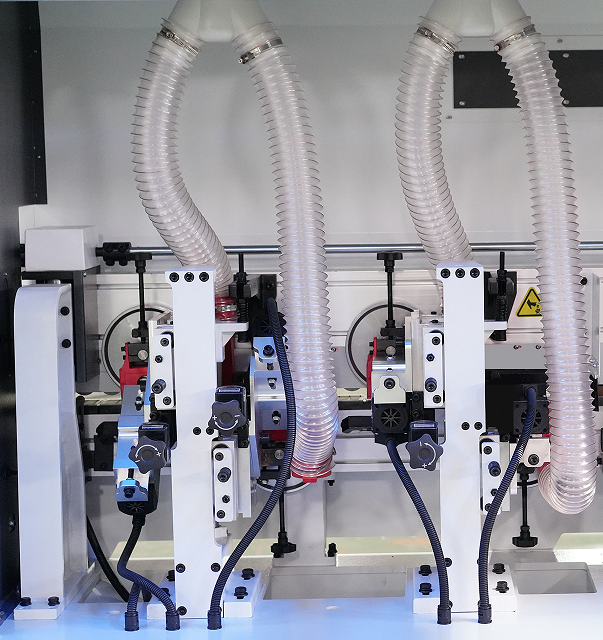

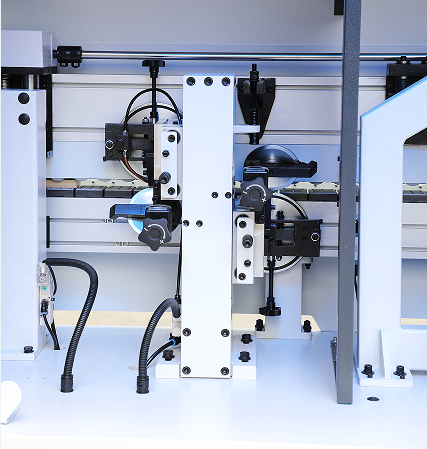

Rough & Fine Trimming System

Use The large and small discs to automatically track the high-frequency and high-speed motor structure, trim the edge banding strips bonded on the upper and lower sides of the plate, and remove the excess edge banding material on the upper and lower sides of the processed plate edge banding strips, so that it can be milled into an R-shaped edge.

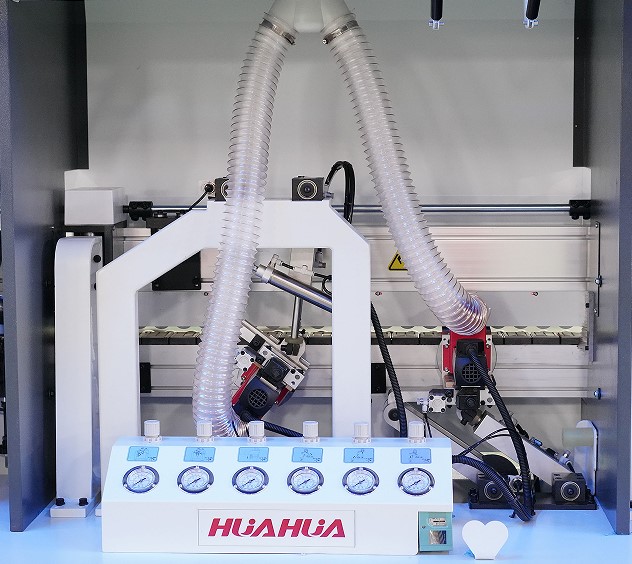

Corner Rounding Unit

Corner rounding unit for soft and postforming workpieces for the processing of the ends of the panel with 0.4-3.0 mm edge material

and 10-60 mm workpiece height, With 2pcs 0.37kw motors. Suitable for straight workpiece edges.

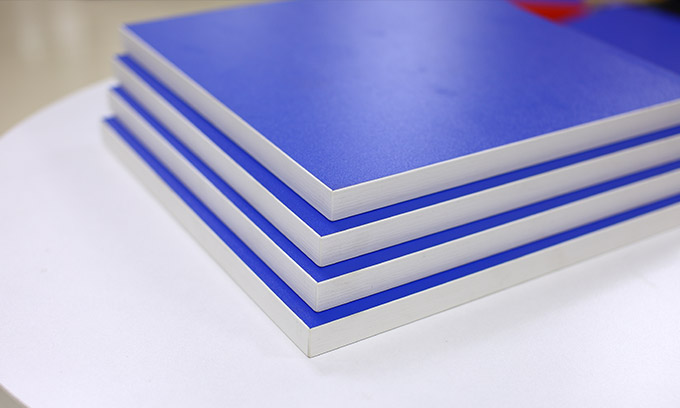

Scraping Unit

The edge trimming knives on both sides of the board scrape off the wavy knife marks caused by the rotation on the edge banding, and the modified R angle is the same as the R angle after finishing, making the upper and lower parts of the board more smooth and tidy.

Buffing Unit

Through the two rotating cloth wheels, the processed panel is cleaned to make the end face of the edge banding more smooth and beautiful, and to keep the polishing wheel worn evenly.

Technical Specifications

| Panel length size | >=120mm | Feeding speed | 15-18-20m/min |

| Panel width size | >=95mm | Total power | 17.1kw |

| Panel thickness | 10-60mm | Working | 0.65mpa |

| Edge width | 13-63mm | Size | 7140*1000*1700mm |

| Edge thickness | 0.4-3.0mm | Weight | 2200kg |

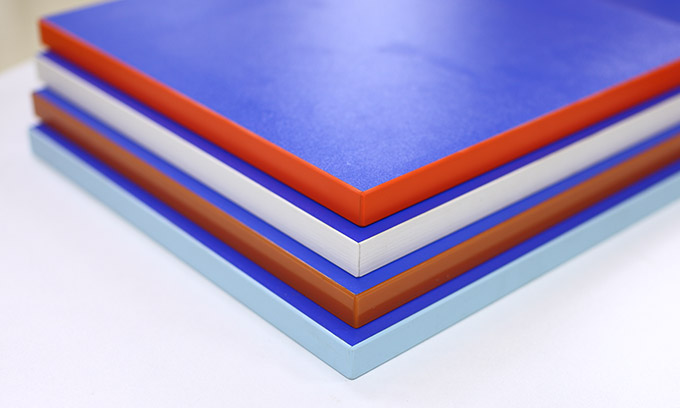

Applications

Automatic edge banding machine, meet various edge banding needs, the necessary machine for furniture, saving time, labor cost.