HH-466RLK

HH-466RLK

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

10-inch touch color screen display

10-inch touch color screen display, easy to operate, save space, safe and reliable operation, simple and friendly interface, with complete operation prompts, concise and clear

Trimming the edge of the plate after cutting

It adopts spiral vacuum cleaner, which has better vacuum effect. It is equipped with a 3.7KW high-power motor and consists of two front and rear milling cutters. The maximum pre-milling height is 40mm (optional 65mm). It can mill corrugations and expansion edges on the surface of the plate to make the seal The edge strips and the board fit more closely, and the integrity and aesthetics are better

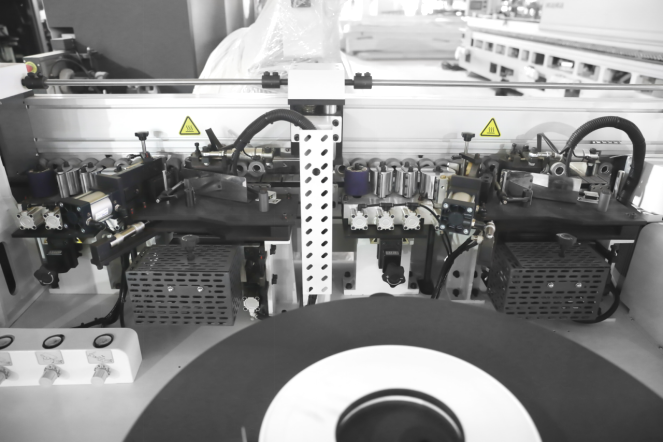

Perfect solution to glue lines

The advantage of the double glue pot is that according to different colors of panels and different colors of edge tapes, you can choose different colors of glue to solve the problem of glue lines.

3+1 pressing wheel for strong bonding

3 pressing wheels + 1 rubber wheel, with built-in scraper to clean the remaining glue, the rubber wheel has better coating and closer fit.

The ends are flush with each other at the same time

The ends are aligned at the front and back at the same time, which is fast and stable and prevents the board from shifting.

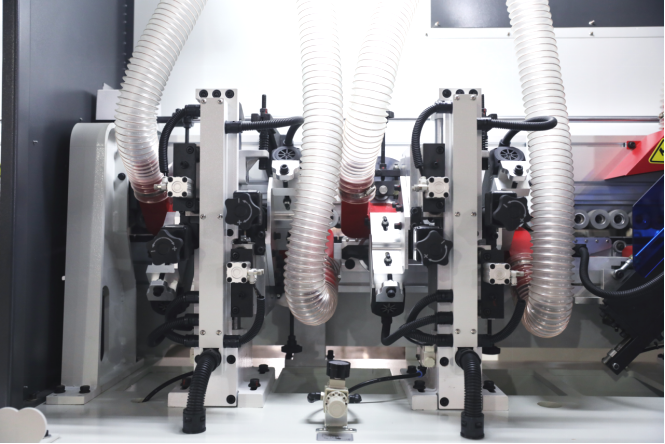

Improve edge sealing effect

Double finishing devices trim the edge, allowing automatic switching between two types of edge banding, saving time and effort, and more effectively improving the edge banding effect.

Trim the four corners of the edge banding strip

The left and right movable profiling wheel rounding device is used to mill the four corners of the edge banding strip bonded to the plate into an R arc shape to meet the tracking trimming requirements of 40×300 long and narrow edges.

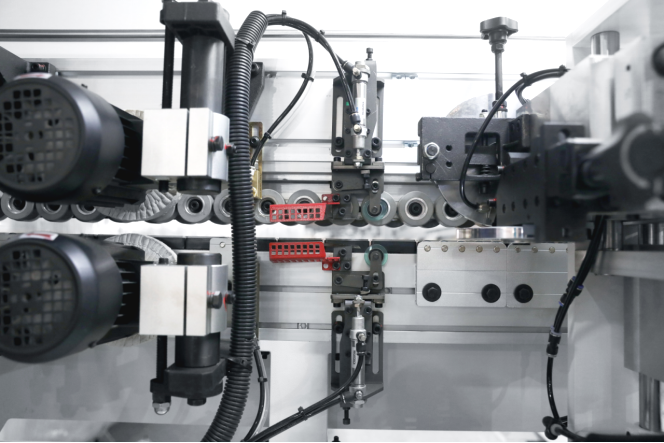

Double scraped edge, high quality edge sealing

The flat-lying scraping adopts precision slider guide, which makes the movement smoother, the structure is more stable, and the scraping effect is more accurate.

Flexible flat scraper to clean excess glue

Remove the remaining glue extruded from the joints of the upper and lower planes of the edge banding attached to the board. Make it less likely to stick to the polishing wheel and reduce the frequency of polishing wheel replacement.

Trimming the edge of the plate after cutting

Use two cloth wheels to clean the processed plate to make the edge sealing end surface smoother and more beautiful, and to keep the polishing wheel evenly worn.

Ensure stability

A high-power conveying motor is used to ensure the stability of the plates when conveyed to each processing unit.

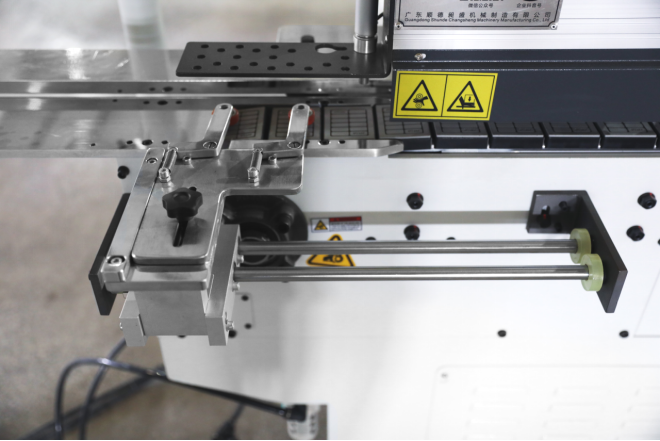

Narrow side auxiliary feeder

The small plate auxiliary feeding device can complete the edge sealing processing of the minimum end 45*200mm and the long and narrow edge 40*300mm.

Technical Specifications

| Min. narrow short side | 45*200mm |

| Min. narrow long side | 40*300mm |

| Panel thickness | 10-60mm |

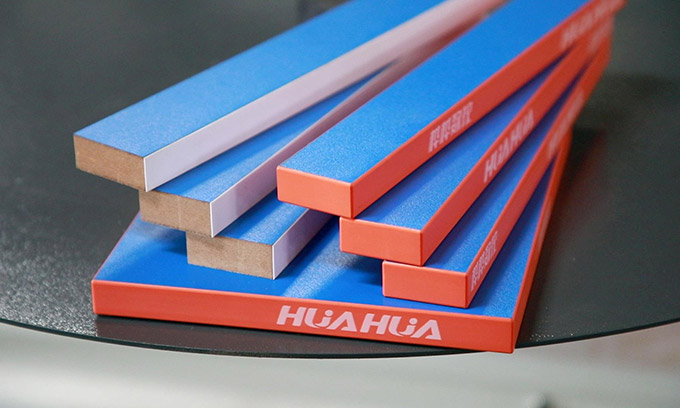

| Tape width | 13-63mm |

| Tape thickness | 0.4-3.0mm |

| Feed rate | 15-18-20m/min |

| Total power | 26kw |

| Working pressure | 0.65mpa |

| Size | 8547mm*1000mm*1900mm |

| Weight | 2700kg |

Applications

Automatic edge banding machine, meet various edge banding needs, the necessary machine for furniture, saving time, labor cost.