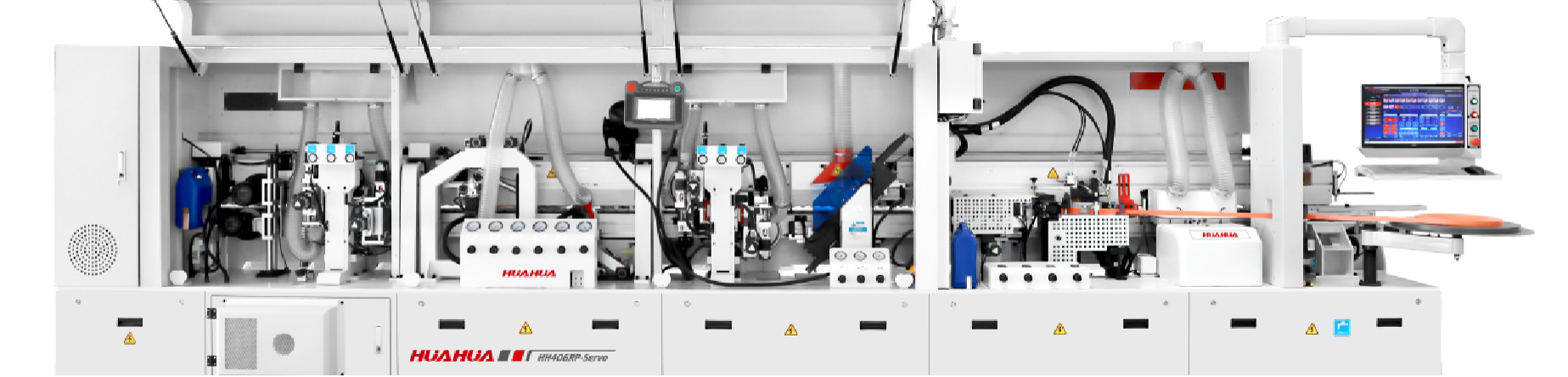

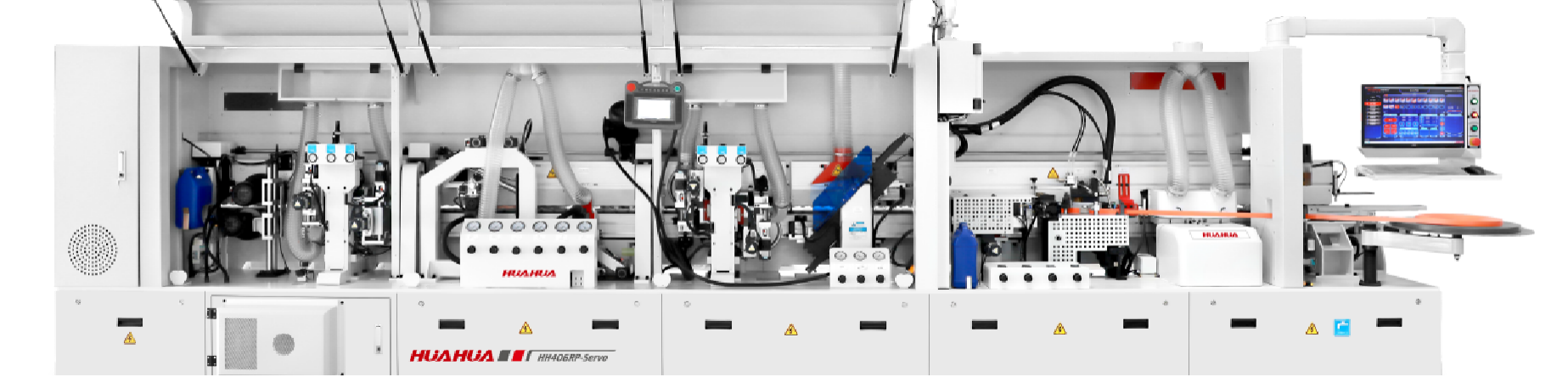

HH-406RP

HH-406RP

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

Computer Screen

Large computer screen,easy to operate

Single-arm suspension design, save space

Simple interface, with complete operating instructions

Servo Positioning Plate

The high-precision control of the servo motor ensures the accurate positioning of the panelduring the edge banding process.

Pre-milling

Spiral dust collection, better effect.

Equippedwith 7kw high-power motor.

Millingpanel surface corrugations and expanded edges.

Maximum pre-milling height 40mm (optional 65mm)

Heating Lamp

Preheat panel edge to prevent it from cracking due to the big temperature difference.

Glue

Double-color clean-freeglue pot + 2kg multifunctional glue machine.

Theclean-free glue pot design avoids the need to frequently clean the glue pot, saving time and labor costs.

2kg multifunctional glue machine (able to use EVA glue)

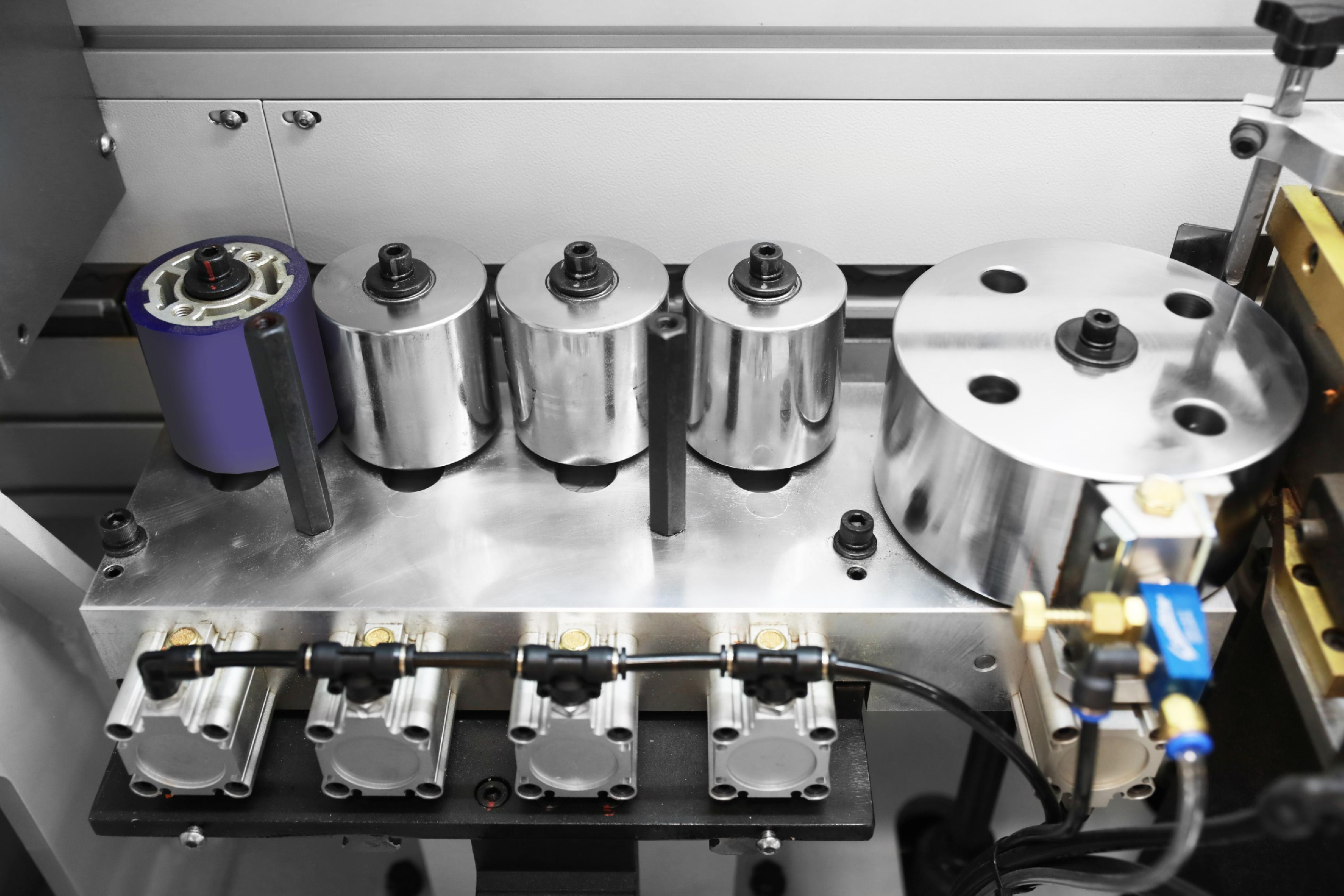

Servo Pressing & Tape feeding

4 strong pressing wheels + 1 rubber wheel, the diameter of the enlarged pressing wheel is 150mm, and the rubber wheel has better coverage and tighter fit.

End cutting

Motor: 0.37kw*2

Adoptautomatic template tracking and high-frequency high-speed motor rapid cutting structure.

Trim the protruding tapes at the front and back of the panel to make them align, ensuring a smooth cut surface.

Dual Positioning Corner Roudning

Motor:3kw*4

Mill the 4 corners of the edge tape bonded to the panel into R arc shapes.

Servo Multi-radius Fine Trimming

Adopt large and small discs automatic tracking,high frequency and high speed motor structure.

Trim the tapes bonded on the upper and lower sides of panel and mill them into R-shape edge.

Servo Multi-radius Scraping

The trimming tool on the both sides of the panel scrape the wave tool marks caused by rotation to make the upper and lower parts of the panel smoother and neater.

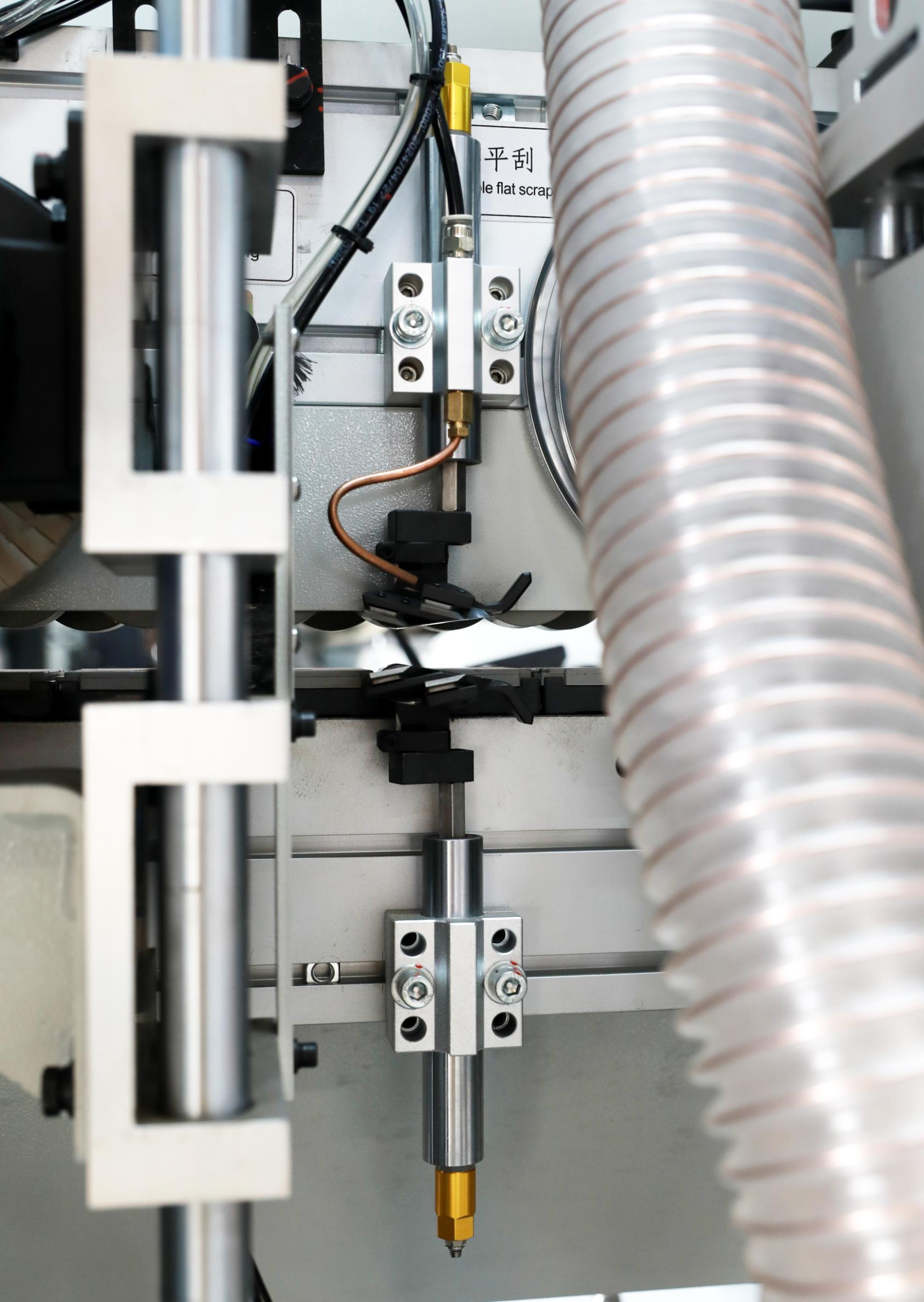

Floating Flat Scraping

Remove the remaining glue extruded from the joints of the upper and lower planes of the edge banding attached to the panel.

Make it less likely to stick to the buffing wheel and reduce the frequency of polishing wheel replacement.

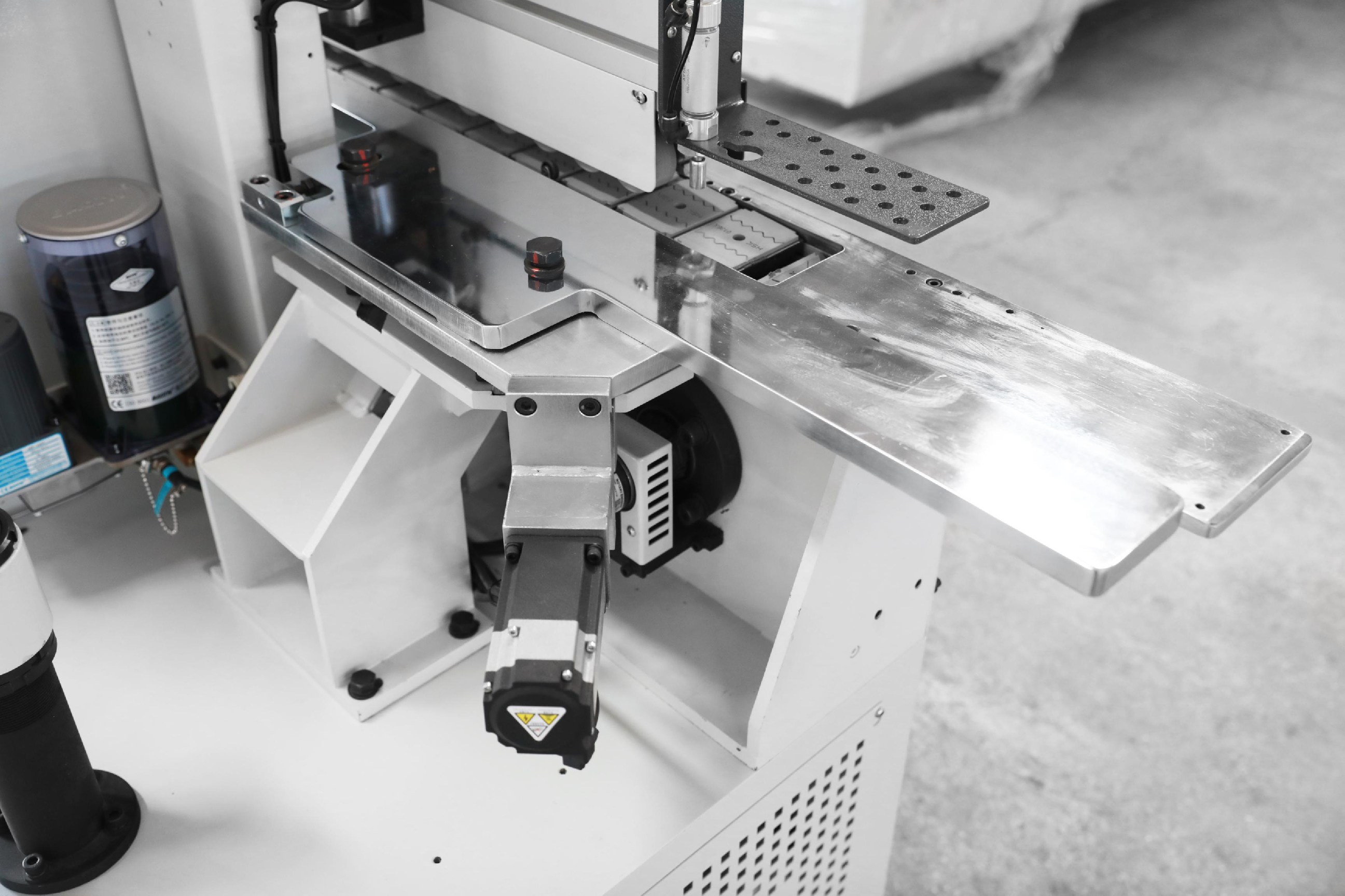

Independent Buffing

Adopting independent beam-column base support structure, the base is stable, the machine operation is more stable, and the edge sealing end surface is smoother and more beautiful.

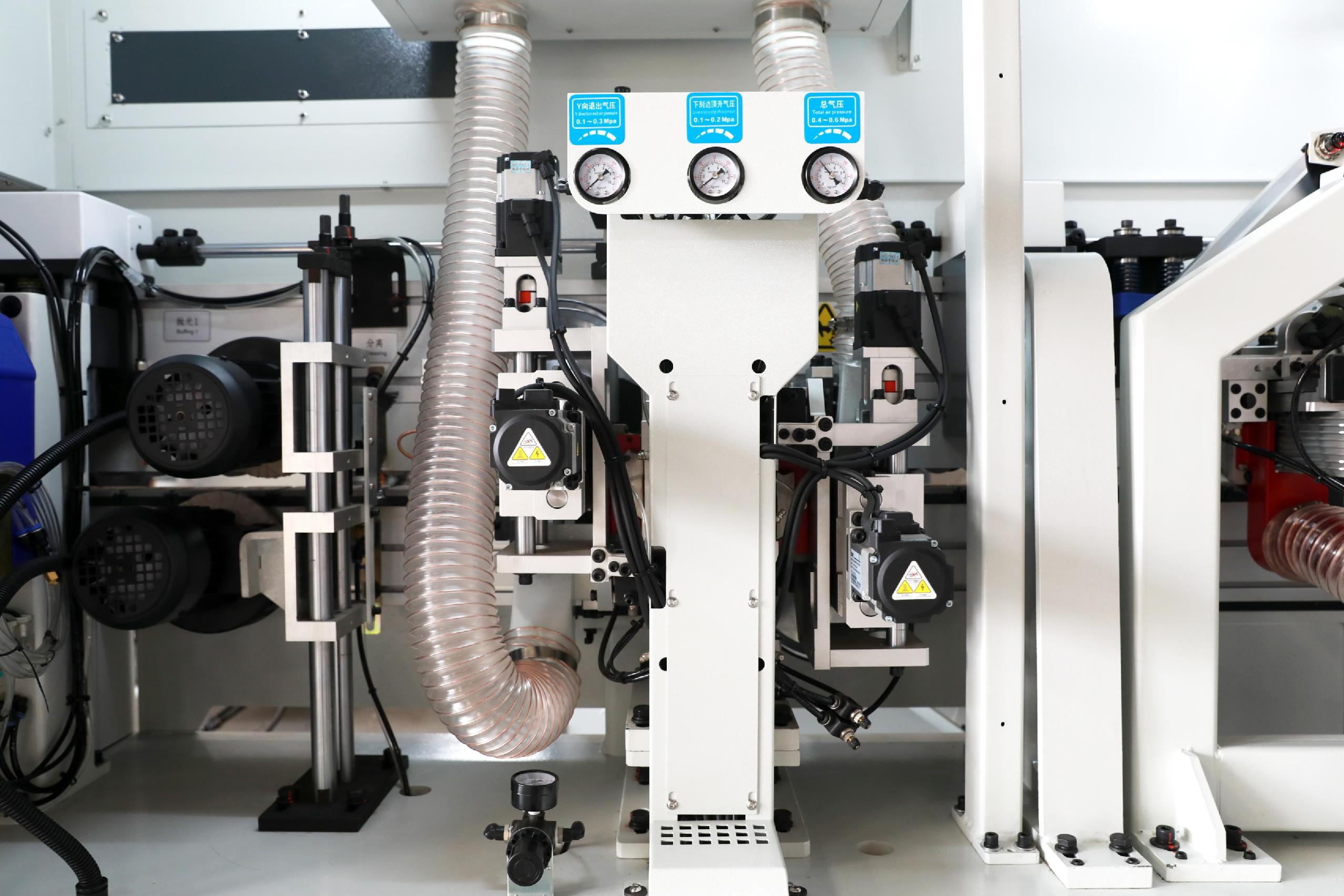

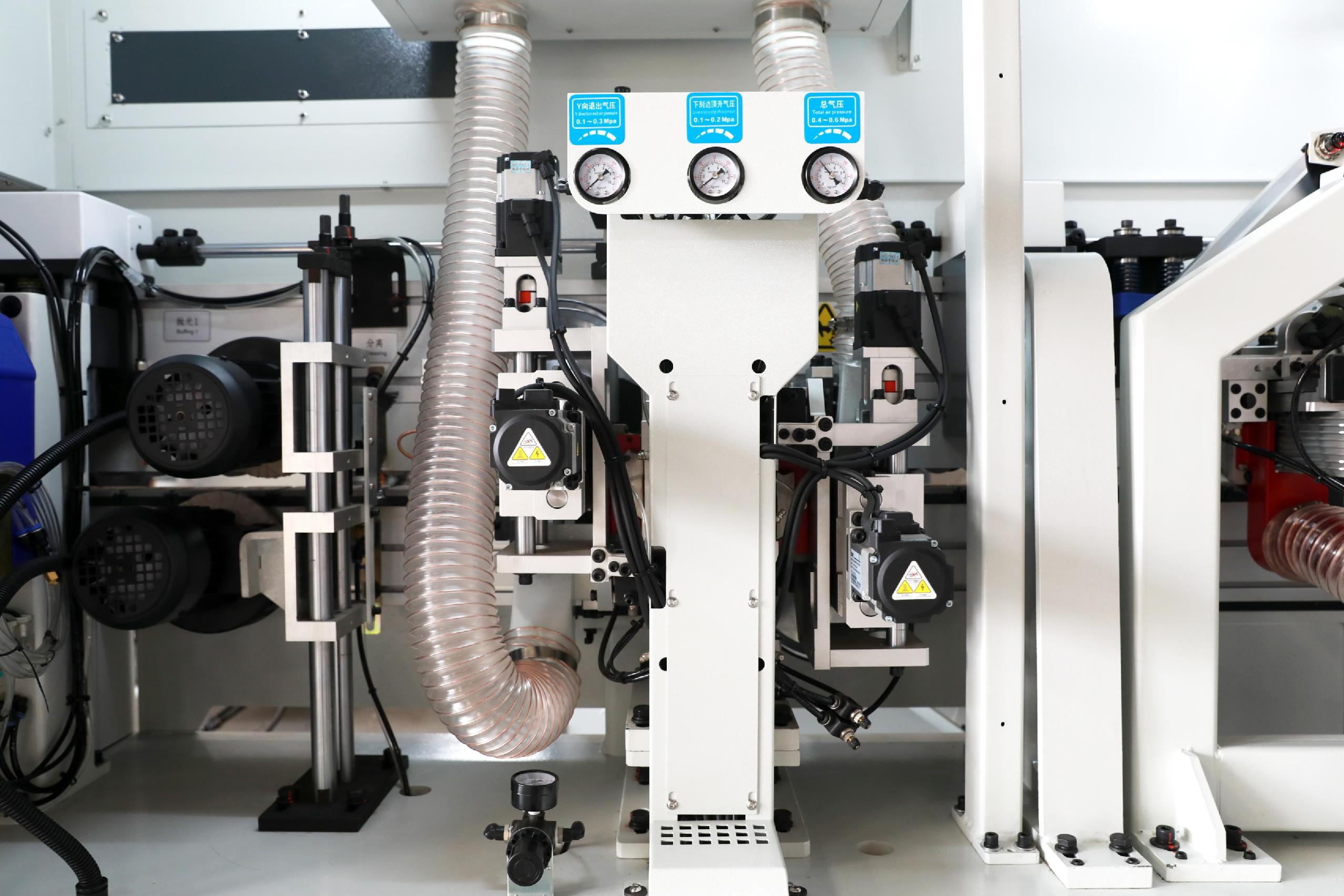

Automatic Lubrication

It lubricates guide rail and chain automatically according to the use time of machine. Ensure long-term operation stability and smooth processing.

Pressing Panel

Ensure the stability of high-speed conveying of panels so that dust is not easy to contaminate the panel conveying surface, improve efficiency and enhance quality.

Tracking Motor

Ceramic ball bearings, life span three times longer than bearings; standard S3 rotation sensor; low temperature rise of the electric spindle. CCC certified, low noise, low vibration, stable operation.

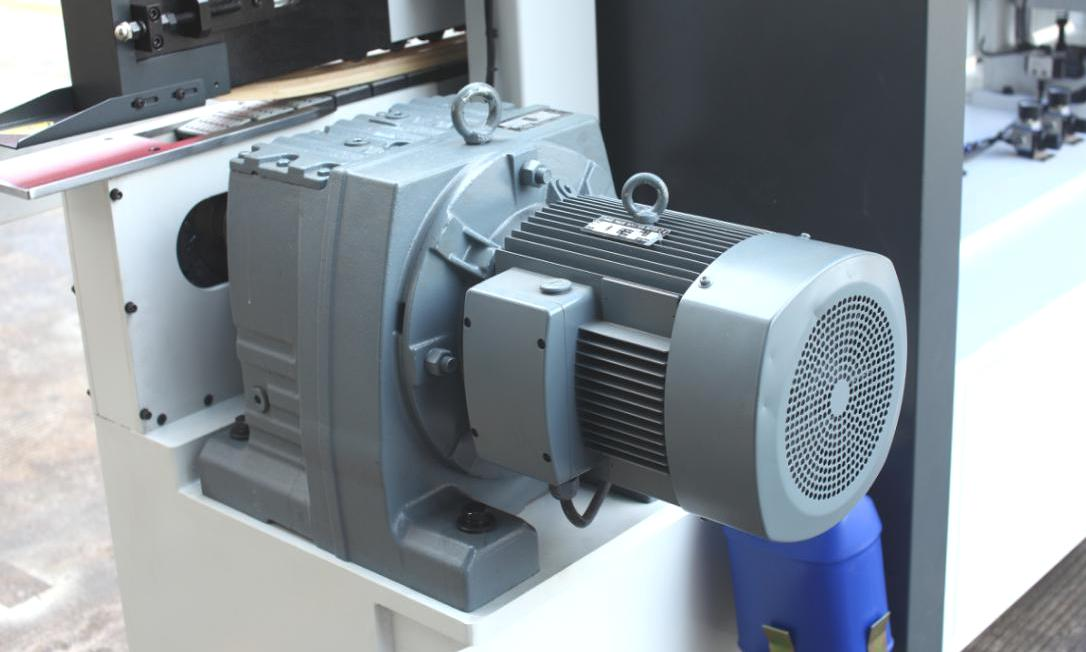

Conveying Motor

High power motor,ensure panel stability when transported to each processing unit.

Thickness Positioning

Automatically adjust the height of the top pressurebeam according to the thickness of the panel.

Automatic positioning of the processing group.

Mechanical digital display of selected sheet thickness.

Pressure Beam Independently Lift

Adopt independent lift for pressing, end cutting and corner rounding unit, prevent panel from shaking and deviating, make precise edge banding.

Technical Specifications

| Panel Length | ≥120mm |

| Panel Width | ≥95mm |

| Panel thickness | 10-60mm |

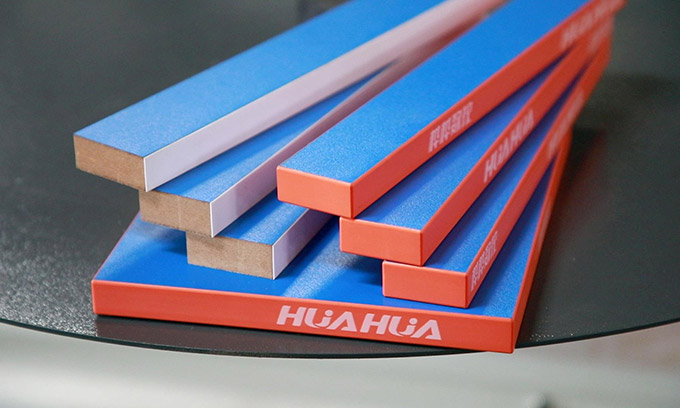

| Tape width | 13-63mm |

| Tape thickness | 0.4-3.0mm |

| Feed rate | 15-18-20m/min |

| Total power | 25kw |

| Working pressure | 0.65mpa |

| Size | 7035*730*2170mm |

| Size | 7035*730*2170mm |

Applications

Automatic edge banding machine, meet various edge banding needs, the necessary machine for furniture, saving time, labor cost.