HH-2506R

HH-2506R

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

7 Inch Color Control Screen

The left and right side are adopt touch color screen display, which is easy to operate, saves space, safe and reliable in operation, simple and friendly interface, with complete operation prompts, concise and clear.

Automatic Press Panel Feeding

There is a feeding press device on the left side to ensure the panel feeding smooth and accurate.

Pressure Wheel Unit

1 big driven wheel and 3 conical contact wheels make up the pressure wheel unit. The big wheel can freely adjust the height according to the width of the edge banding , ensure that the edge banding is not easy to shift.

Press the edge banding glued on the panel through four pressing wheels to make the panel and the edge banding more firmly bonded.

End Cutting Unit

End cutting unit with two high frequency motors .

0.37 kW (1 HP); 12000 rpm;

Through the precise linear guide rail movement, the automatic tracking of the profile and the fast cutting structure of the high-frequency high-speed motor are used to trim the protruding edge banding strips at the front end of the plate and the protruding edge banding strips at the rear end of the plate.

Make it flush with the front and back ends of the sheet to ensure that the cut surface is flat and smooth

Rough&Fine Trimming Unit

Adopt large and small discs to automatically track the high-frequency and high-speed motor structure, trim the edge banding strips bonded on the upper and lower sides of the panel, and remove the excess edge banding material on the upper and lower sides of the edge banding strips on the panel, so that it can be milled into an edge with an R arc.

Corner Rounding Unit

Corner rounding unit for soft and postforming workpieces for the processing of the ends of the panel with 0.4-3.0 mm edge material and 10-60 mm workpiece height, With 2pcs 0.37kw motors. Suitable for straight workpiece edges. Minimum workpiece length 300mm.

Thickness Positioning - Automatic Adjustment

The height of the top pressure beam is automatically adjusted according to the thickness of the panel, and the processing group is automatically positioned. mechanical digital display

Choose the thickness of the board.

Double-side Edge Banding

Synchronous conveying device, standardized edge banding process, flexible edge banding.

Left and Right Conveying

Left and right conveying device, through-type processing, shorten panel distance, maximize the utilization of each edge banding machine.

Moving Side- automatic adjustment

The right side is the moving side , which can move laterally with a stroke of 2650mm.

Distance control - automatic adjustment

The safety distance control device prevents the panels from colliding with the panel and ensures the normal operation of the machine.

Option- Up and down grooving

Option – grooving function

There are 5.5kw motor and 7.5kw motor for choosen .

Technical Specifications

| Panel length | ≥300mm |

| Panel width | ≥300mm |

| Panel thickness | 10-60mm |

| Tape width | 13-63mm |

| Tape thickness | 0.4-3.0mm |

| Feeding speed | 15-18-20m/min |

| Total power | 38kw |

| Working pressure | 0.65mpa |

| Overall size | 7040*4810*1700mm |

| Weight | 5000kg |

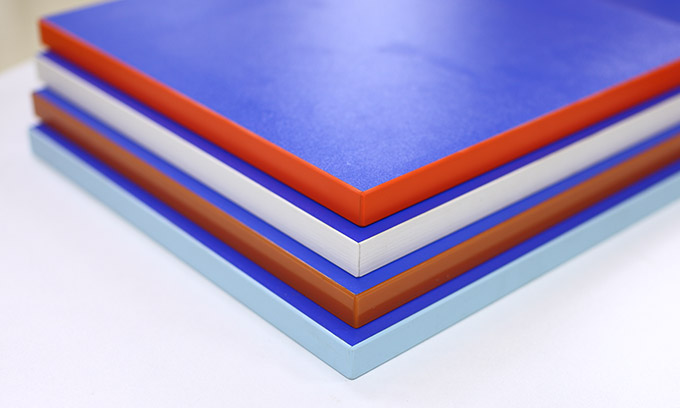

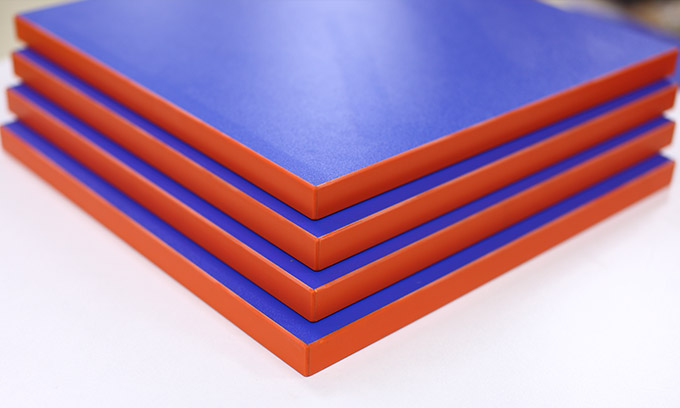

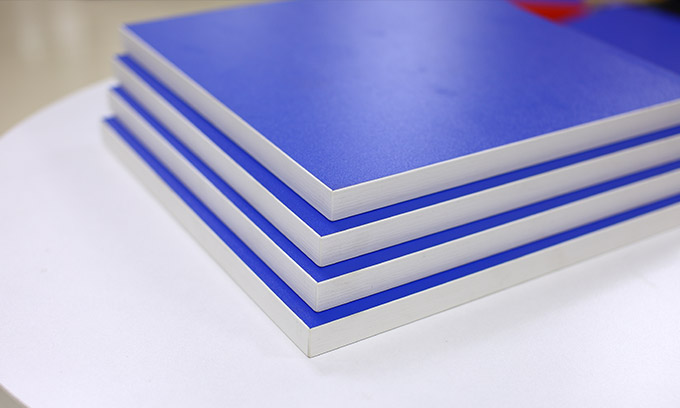

Applications

Automatic edge banding machine, meet various edge banding needs, the necessary machine for furniture, saving time, labor cost.