When it comes to furniture manufacturing, edge banding plays a crucial role in achieving a polished and refined finish. At HUAHUA, we understand the significance of edge banding in creating high-quality furniture that meets the demands of the market. In this article, we will explore the importance of edge banding and how it pertains to different material specifications. With our advanced solutions and expertise as an edge banding manufacturer, HUAHUA is here to revolutionize your furniture production process.

Find Edge Banding in Your Furniture

The presence of edge banding in furniture depends on the overall material specification. Solid wood products typically do not require edge banding except in areas where solid wood cannot be used, such as veneer core plywood or MDF used for wardrobe doors. Even when solid wood is used for case sides and drawer fronts, many customers opt for high-pressure laminate tops, which necessitate the use of edge banding. Plywood or laminate materials also require edge banding to achieve a seamless and refined appearance.

Choose HUAHUA as Your Edge Banding Manufacturer

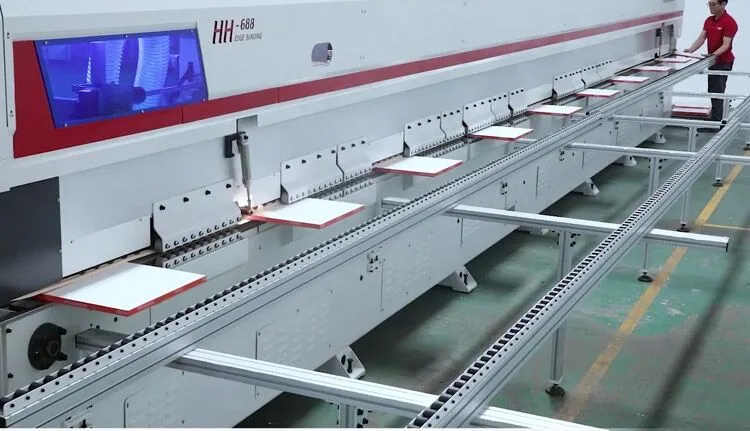

HUAHUA specializes in providing high-quality edge banding solutions that cater to a wide range of material specifications. Our automatic edge banding machines are optimized to deliver exceptional results, ensuring a precise and durable bond between the banding tape and the panel. With our advanced technology, you can rely on HUAHUA to meet your edge banding requirements, regardless of the materials used in your furniture manufacturing process.

Enhancing Your Furniture with HUAHUA’s Edge Banding Expertise

HUAHUA’s edgebanding machines are equipped with cutting-edge features such as well pre-mill, water-proof PUR glue, auto-track trimming, and corner rounding & polishing. These features ensure that your furniture achieves a flawless and professional finish. By utilizing well pre-milling, our machines guarantee a strong bond between the banding tape and the panel, resulting in a secure and long-lasting edgebanding solution. The water-proof PUR glue used in our machines provides added protection against moisture, safeguarding the wood panels from potential damage.

Moreover, our auto-track trimming technology, with double trimming discs, automatically removes excessive glue and tape, resulting in a smoother appearance of the panels. Additionally, the corner rounding device and cloth polishing wheels perfect your panel processing line, allowing you to produce impeccable panel furniture that meets the highest standards of quality.

Conclusion:

In the world of furniture manufacturing, edge banding plays a crucial role in achieving a polished and refined appearance. Whether you’re working with solid wood, veneer core plywood, MDF, or laminates, edge banding is essential to ensure a seamless and durable finish. As an edge banding manufacturer, HUAHUA understands the importance of delivering superior solutions tailored to your specific material specifications.

With our advanced automatic edge banding machines, we offer a range of features including well pre-mill, water-proof PUR glue, auto-track trimming, and corner rounding & polishing. These features enhance the quality, durability, and visual appeal of your furniture, satisfying the demands of the end-market. Trust HUAHUA as your edge banding manufacturer and experience the difference in your furniture manufacturing process.