In today’s rapidly evolving industrial landscape, the trend of smart manufacturing is truly unstoppable. This relentless pursuit of efficiency, productivity, and innovation drives this transformation. Smart manufacturing leverages advanced technologies to create more agile and responsive production systems. For furniture manufacturers, this shift is particularly significant. The traditional methods of furniture production are being revolutionized by integrating smart technologies, leading to more efficient and precise manufacturing processes.

In the furniture manufacturing industry, many factories are now transforming their operations into smart manufacturing factories by investing in turnkey furniture production lines. This transformation not only boosts production efficiency but also enhances product quality and reduces operational costs. The concept of smart manufacturing aligns perfectly with the demands of Industry 4.0, where connectivity and automation are paramount. For furniture factories, the implementation of smart manufacturing means embracing a new era where production lines are interconnected, and machines communicate seamlessly.

This article will delve into achieving smart manufacturing in furniture production. We will explore why a turnkey furniture production line is essential in accelerating this transformation. By integrating smart technologies into the furniture production line, manufacturers can significantly enhance their production capabilities, streamline manufacturing operations, and stay competitive in a fast-paced market.

Introduction to Smart Manufacturing

Smart manufacturing is a cutting-edge approach that combines advanced technologies with traditional manufacturing processes to create highly efficient and adaptive production systems. At its core, smart manufacturing utilizes interconnected machines, sensors, and software to automatically operate the production and automatically collaborate with every machine from every stage of the production line. This approach enables manufacturers to optimize their operations, increasing the production capacity.

Key components of smart manufacturing include the Internet of Things (IoT), which connects machinery and equipment to the Internet, and computing capability, which assists to act the vast and complicating operation simultaneously. Additionally, automatic unmanned production plays a crucial role, allowing for seamless and precise control and improving the efficiency in manpower distribution over production processes.

By adopting smart manufacturing devices, companies can achieve higher productivity, better quality control, and greater flexibility in their manufacturing operations.

Benefits of Transforming into Smart Manufacturing

Transforming into smart manufacturing holds immense potential for furniture manufacturing businesses. By adopting smart manufacturing practices, furniture factories can achieve significant improvements in several key areas:

1. Increased Efficiency

Automatic streamline production processes, reducing downtime and minimizing waste. This leads to faster production cycles and higher output.

2. Enhanced Quality Control

Smart manufacturing systems monitor every aspect of the production line, ensuring consistent quality and reducing the likelihood of defects. This results in higher-quality products and increased customer satisfaction.

3. Cost Savings

By optimizing resource usage and improving operational efficiency, smart manufacturing can significantly lower production costs. Predictive maintenance helps avoid costly downtime and repairs.

4. Flexibility and Adaptability

Smart manufacturing enables quick adjustments to production lines in response to market demands. This flexibility allows furniture manufacturers to offer a wider variety of products and meet customer needs more effectively.

The Role of Turnkey Automated Furniture Production Lines

In the circle of furniture transformation to smart manufacturing, turnkey automated furniture production lines are integral. These comprehensive solutions streamline the integration of advanced technologies into existing production systems, enabling a seamless transition to smart manufacturing.

1. Integrated Solutions

Turnkey production lines offer a complete package, including machinery, software, and support, ensuring all components work harmoniously. This integration simplifies the implementation of smart technologies and minimizes disruptions.

2. Better Production Continuity and Precision

As the name suggests, the automated furniture production line can handle repetitive tasks with high precision and speed automatically, significantly improving production continuity to meet large orders on tight delivery dates. Besides, being controlled by computing software, an automated manufacturing line reduces human error and customizes easily, ensuring that furniture manufacturers can deliver high-quality and still attractive woodworking pieces.

3. Scalability

Turnkey solutions in furniture production lines are designed to be scalable, allowing furniture manufacturers to expand and adapt their production lines as their business grows. This scalability is essential for staying competitive in a dynamic market.

4. Cost-Effectiveness

By providing a ready-to-use solution, turnkey production lines reduce the need for extensive development and labor costs, resulting in cost savings and faster deployment.

Incorporating a turnkey automated manufacturing line is a strategic move that facilitates the transition to smart manufacturing, bringing substantial benefits to furniture manufacturers.

Introducing Huahua’s Furniture Production Line A8

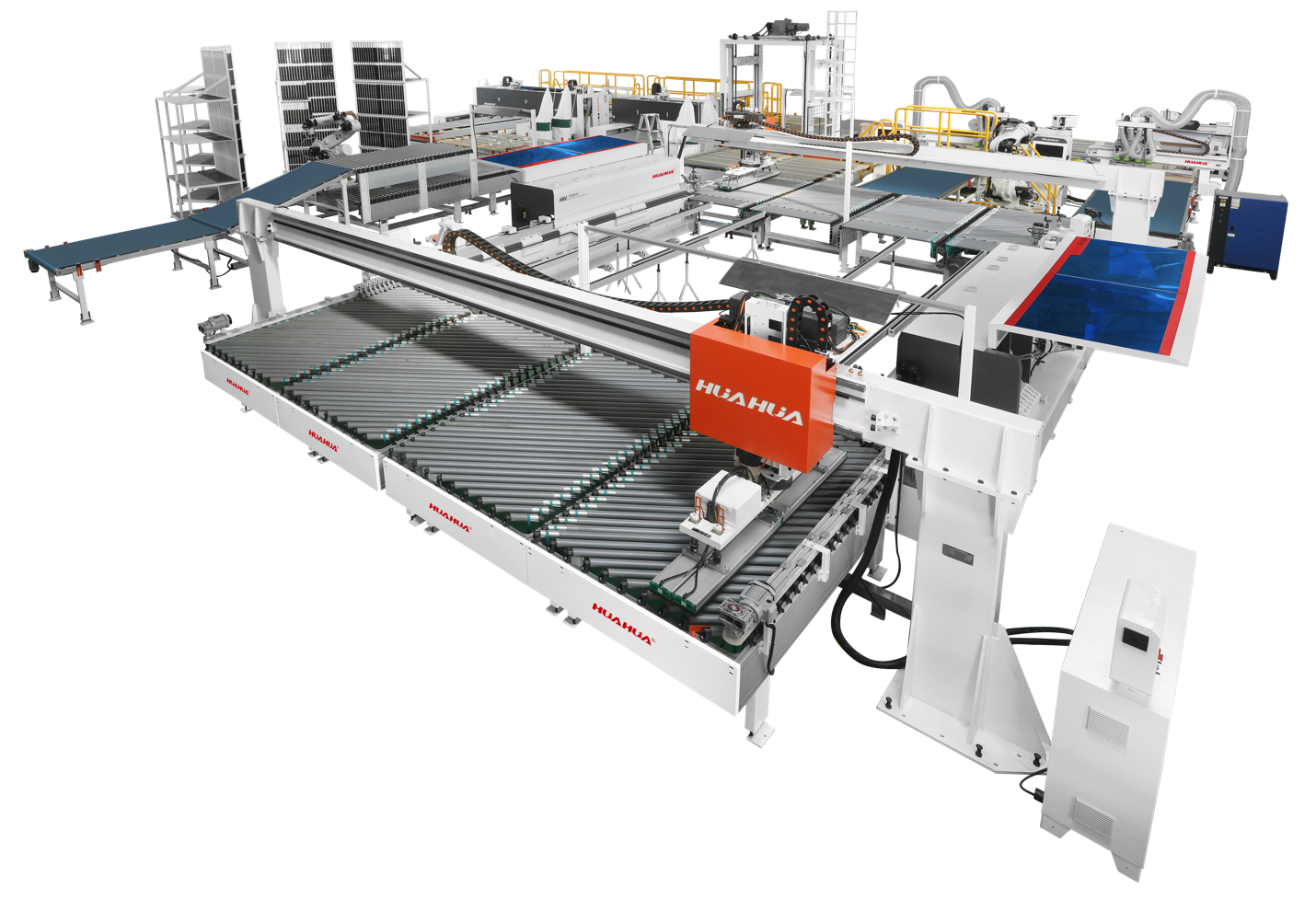

Our Huahua’s Furniture Production Line A8 is a state-of-the-art solution designed to bring smart manufacturing to your factory. Here’s how it stands out:

Combination of Powerful Machines

Our Furniture Production Line A8 comprises 2 CNC router operating platforms in one solution, enhancing the efficiency of woodworking. It also includes 2-side (left and right) edge banding machines for seamless and durable edge finishing and 2 6-side drilling machines that provide comprehensive drilling capabilities from all angles. Additionally, this line features a book rack three-dimensional sorting system that optimizes the organization and sorting of materials.

As a result, this furniture turnkey manufacturing solution is with a production capacity of 25 wood pieces per hour. However, the entire installation only requires a space of 665 m2, making it a substantial yet highly productive addition to any furniture factory setting.

Smart Features

Our HUAHUA Furniture Production Line A8 is an ideal choice for furniture businesses aiming to transform their factories into smart manufacturing hubs. It supports an information-based furniture production mode that seamlessly integrates planning, informatization, and equipment. This holistic approach allows furniture manufacturers to achieve rapid, digitized production, significantly enhancing their operational efficiency.

Besides, this furniture manufacturing production line is equipped with the HHM System, an independently developed software that is user-friendly and significantly boosts overall production efficiency, and MES (Manufacturing Execution System), which offers real-time monitoring of the machining process.

This furniture production line also utilizes top-tier brands such as Sike sensors, Delta inverters, and Schneider’s weak current components, ensuring high-quality performance and durability.

So, these advanced features make our Furniture Production Line A8 an intelligent, efficient, and reliable choice for modern factories to start smart manufacturing.

Customized Features

For those who are in the transition to smart manufacturing care the budget as well. We can customize a smart manufacturing solution for you, no matter whether you want to upgrade from the existing production lines or start from the entire factory. Every furniture manufacturer can choose the level of transformation that best fits the current capabilities and future goals.

Conclusion

Smart manufacturing is revolutionizing the furniture industry, offering unparalleled efficiency, quality, and adaptability. Transforming your furniture production line with smart technologies is essential for remaining competitive and meeting modern market demands.

Our Huahua‘s Furniture Production Line A8 exemplifies the best in smart manufacturing solutions. From advanced sensors and operating systems to powerful equipment and customized solutions, we can always provide our clients with everything needed to upgrade your factory. With over 30 years of experience in furniture manufacturing machines, you can trust us for innovative, reliable, and cost-effective furniture manufacturing solutions that keep you ahead in the industry. Contact Huahua today!