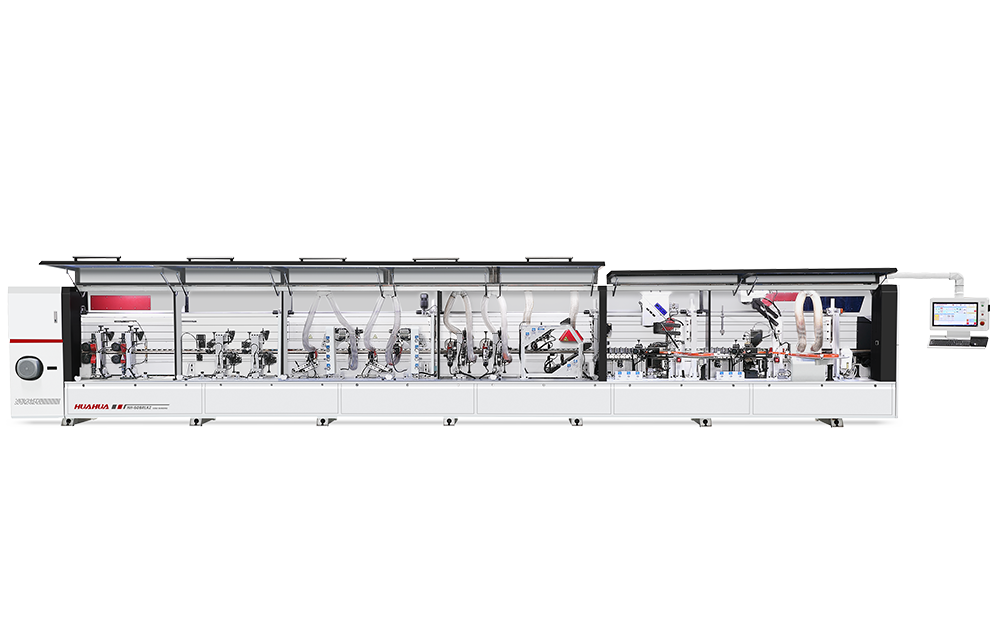

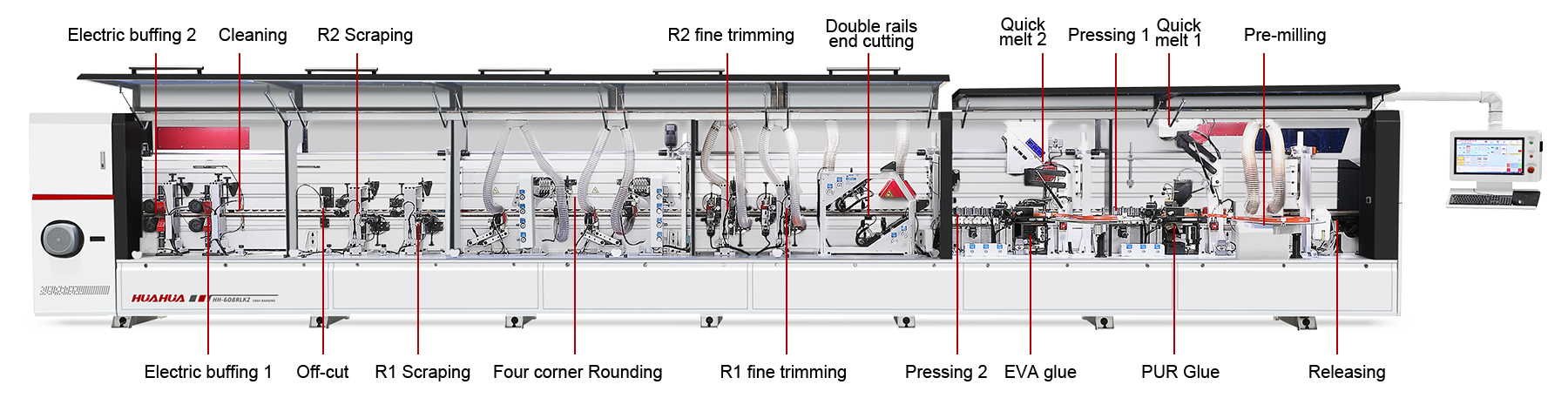

HH-608RLKZ

HH-608RLKZ

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

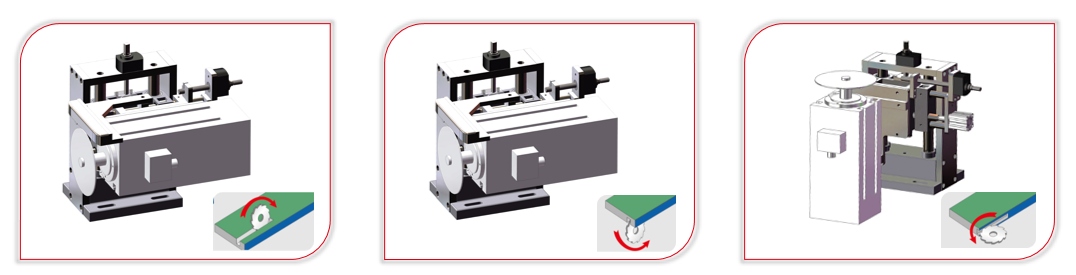

Double Rails End Cutting Unit

0.37 kW (0.5 HP); 12000 rpm; saw blades Z 30 D-104 x 22 x 3.2 mm. Two motors up & down moving by sliding rails quickly cut the front and rear edge banding tape,and the two saw blades are matched before and after to achieve high precision and high efficiency.

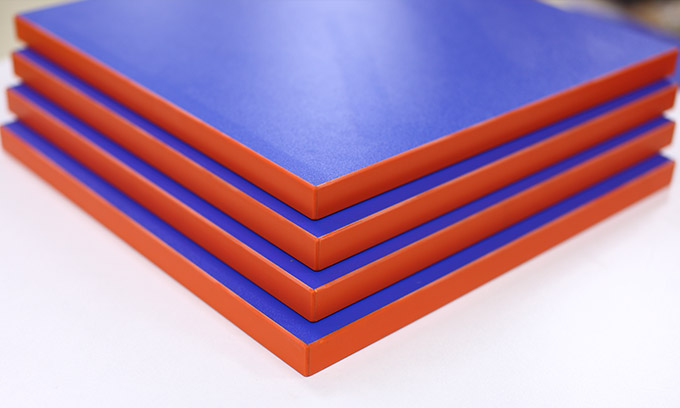

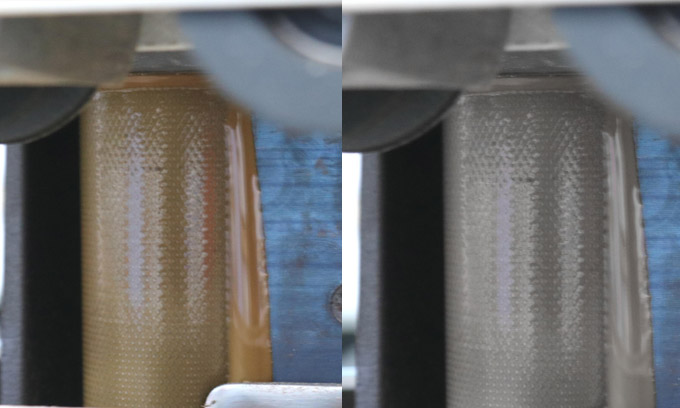

Double Gluing Unit

The advantage of the double glue pot is that, according to different colors of panels and different colors of edge banding, we can choose different colors of glue.Solve the glue line problem.

Heavy Duty Aluminum Pressure Beam

The heightened heavy-duty pressure beam increases the stability of the whole machine during processing, and it is stable and not easily deformed in long-term use.

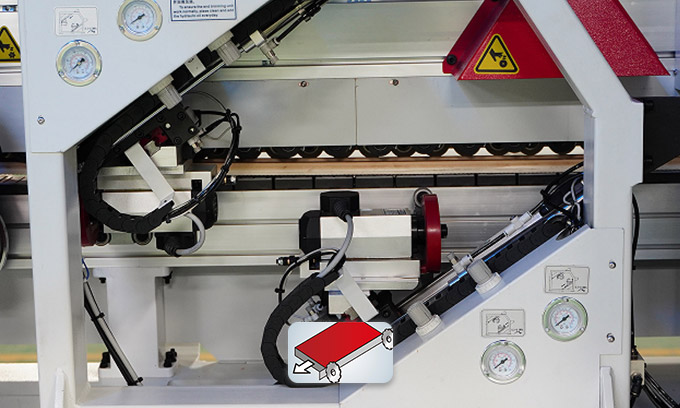

High Speed 4 Corner Rounding

Corner rounding unit for soft and postforming workpieces for the processing of the ends of the panel with 0.4-3.0 mm edge material and 10-40 mm workpiece height, with 4pcs 0.37kw motors. With 4pcs 6 teeth R2 cutters. ( 3mm thickness edge belt will use R3) size 68*16*16*6 teeth.

The fastest speed of corner rounding is 26m/min,can achieve 4 different profiling effects.

Direction Chip Removal Scraping

Directional air blowing and chip removal, reducing chip jamming of large and small circular disc.

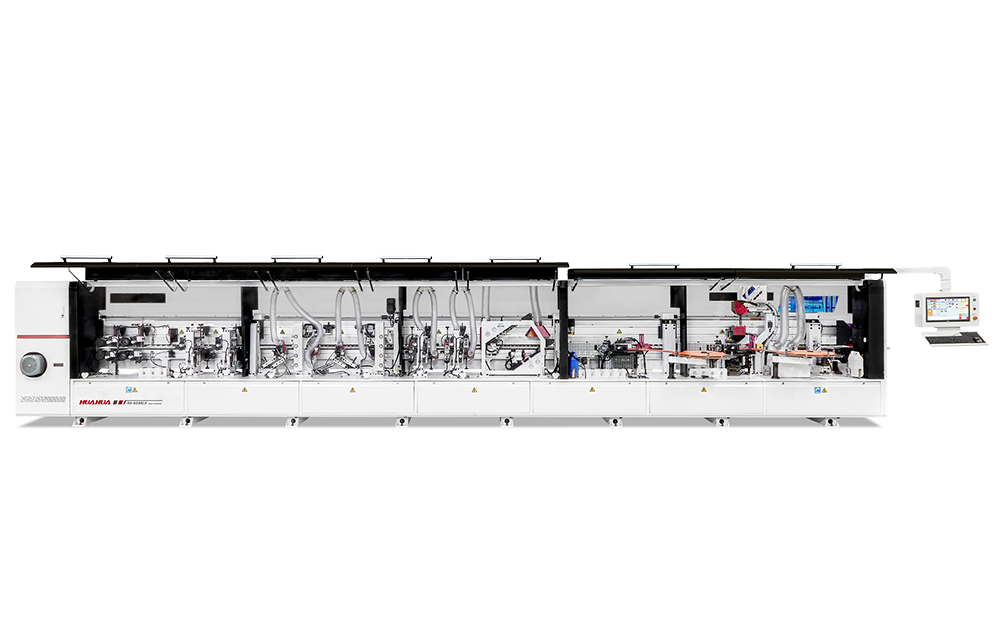

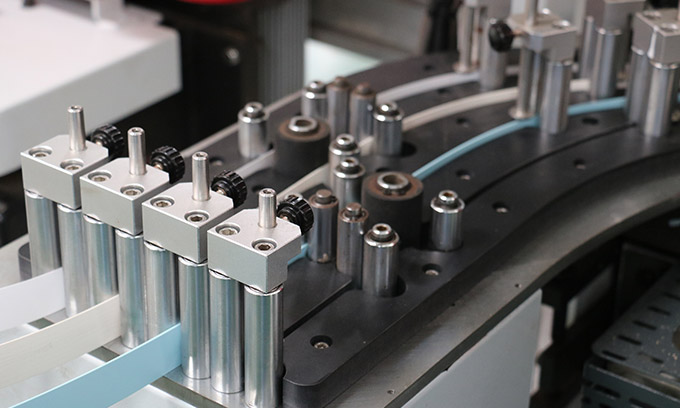

Heavy-duty Steel Structure Integrated Rail

The guide rail base adopts integral welding and annealing, the frame has high rigidity, the conveying guide rail and the frame are integrally connected, and the straightness of the guide rail is precisely processed to ensure the straightness of 0.1mm/2m.

Vertical Disc Scraping Module

Change from a small vertical disc to a large horizontal disc. The structure of the horizontal disc is stronger and has higher impact resistance. The vertical disc is easy to process, and it is easier to ensure verticality and radial runout, reducing the need for processing. Errors lead to scraping effects.

Turbine Worm Lifting Independent

Adopt independent turbine worm lift and precision slider drive to improve stability and synchronization.

Electric Double Buffing

Two groups of electric buffing are used to buff the edge of the panel. The electric buffing runs more smoothly and the buffing effect is more beautiful.

Optional

Four -channel automatic tape change.

Can set four kinds tapes according to production request, Efficient and flexible production, save time, save labor.

“One key to change four kinds tapes, reduce the tapeschanging time, the efficiency is four times of the normal edge banding machine.”

Optional

Custom slotting available.

Top slotted(5.5kw/7.5kw)

Bottom slotted(5.5kw/7.5kw)

Side slooted(5.5kw/7.5kw)

Technical Specifications

| Panel length | ≥120mm |

| Panel width | ≥120mm |

| Panel thickness | 10-60mm |

| Tape width | 13-63mm |

| Tape thickness | 0.4-3.0mm |

| Feed rate | 20-23-26m/min |

| Total power | 31.8kw |

| Working pressure | 0.65mpa |

| Size | 11700*1100*1974mm |

| Weight | 4000kg |

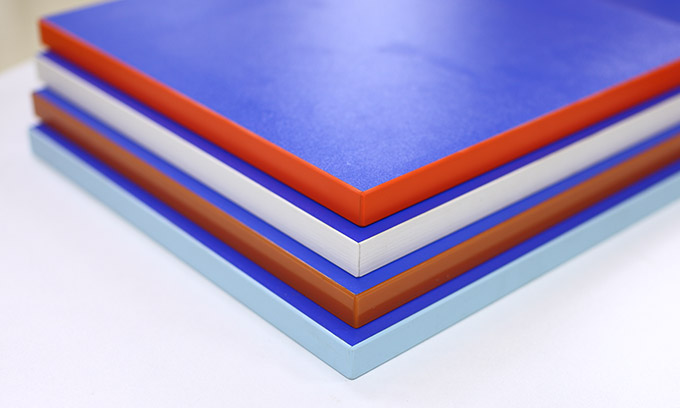

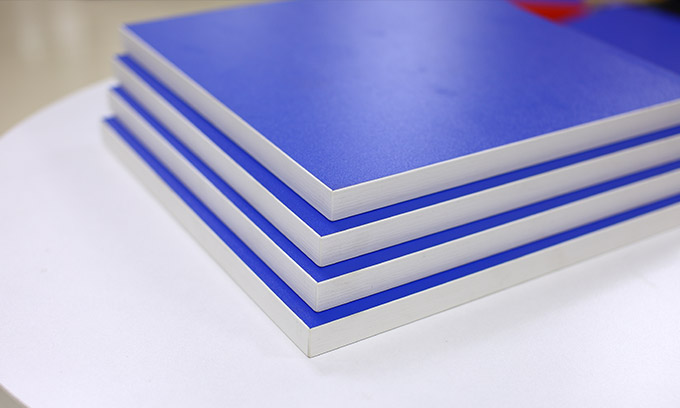

Applications

Automatic edge banding machine, meet various edge banding needs, the necessary machine for furniture, saving time and labor cost.