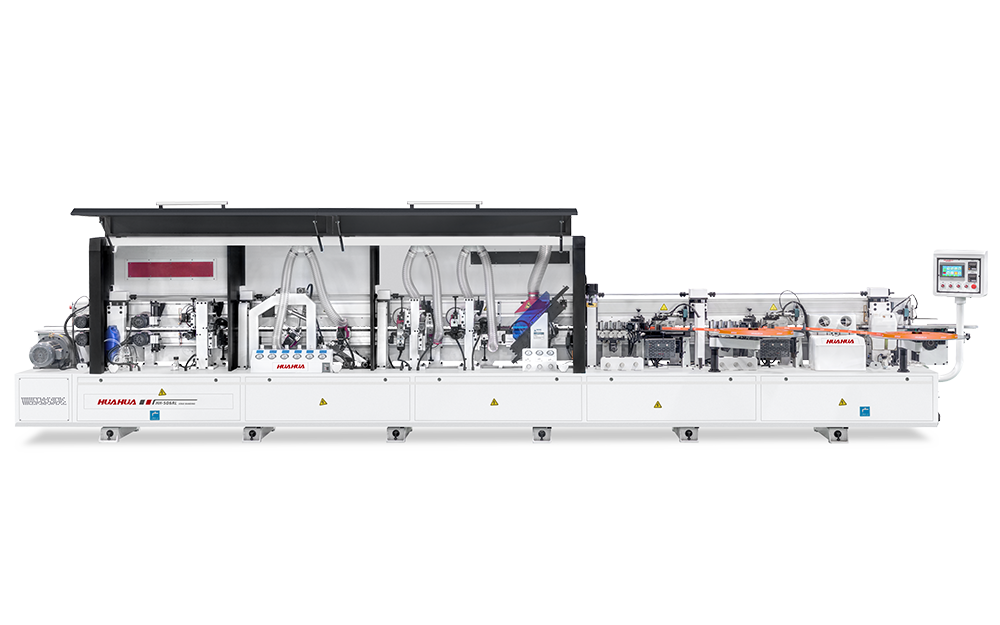

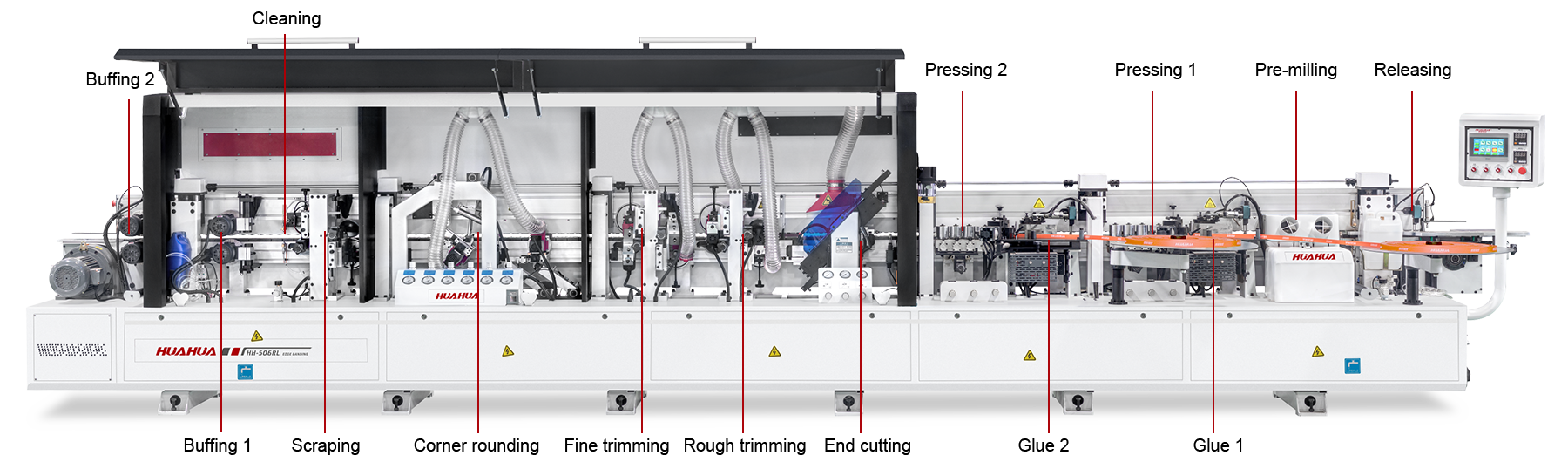

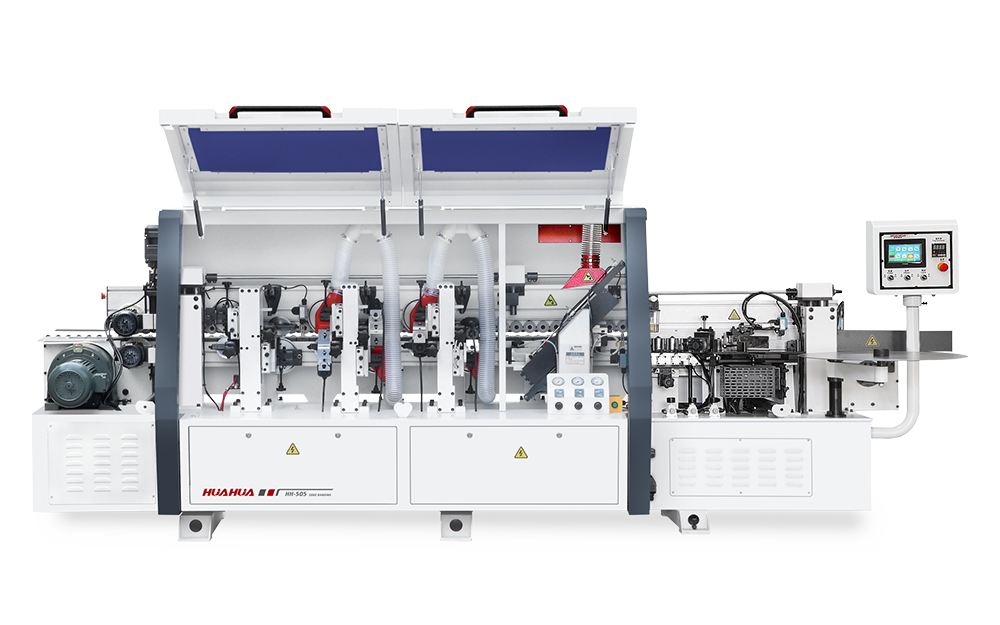

HH-506RL

HH-506RL

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

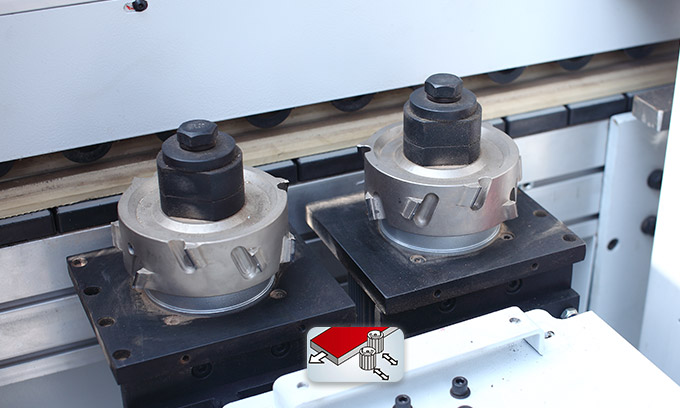

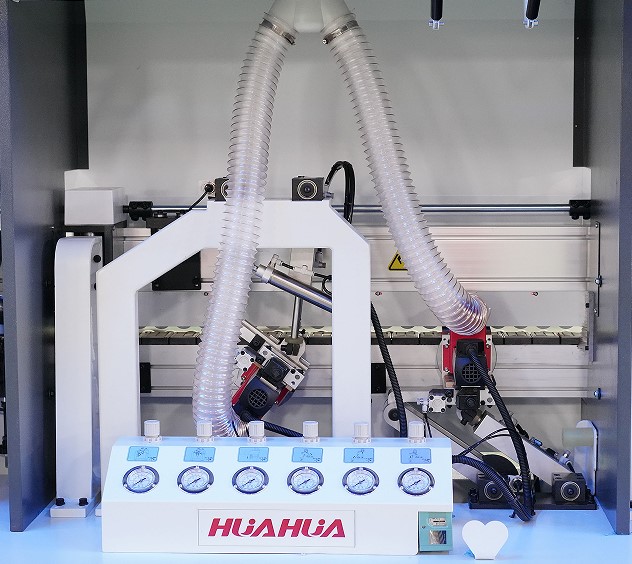

Pre-milling

Trimming the edge of the panel after cutting

Equipped with a 2.2KW high-power motor, it is composed of two milling tools at the front and rear. The maximum pre-milling height is 40mm (65mm is optional).

Milling the corrugated of the surface of the board makes the edge banding and the board more tightly bonded, and the integrity and aesthetics are better.

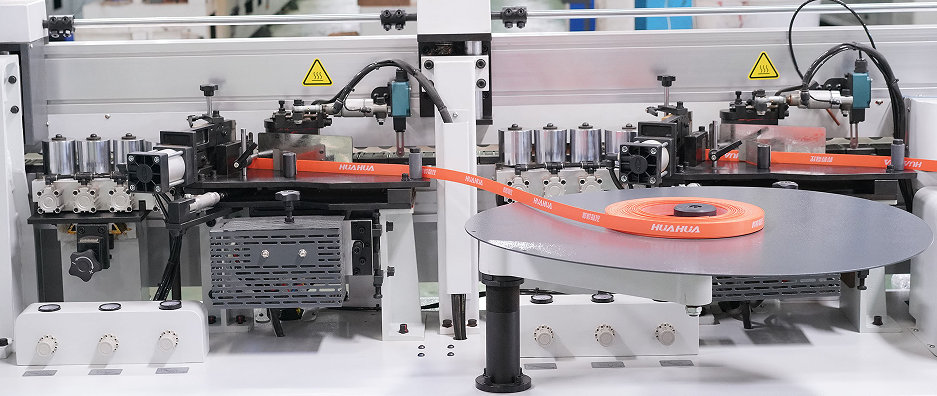

Doubel Pressing and Glue Pot

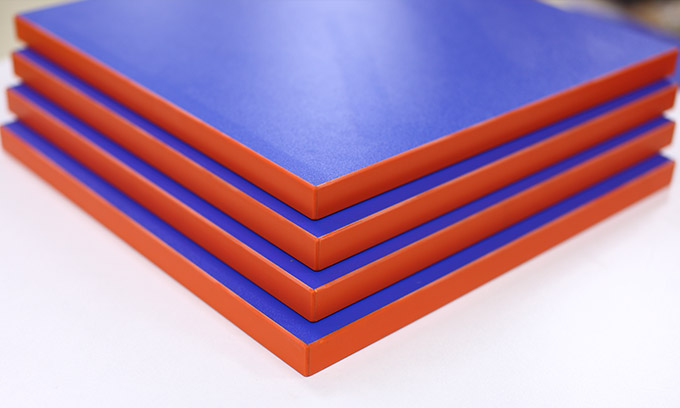

The advantage of the double-glue pot is that it can choose different colors of glue according to different colors of panels and different colors of edge banding to solve the problem of glue lines.

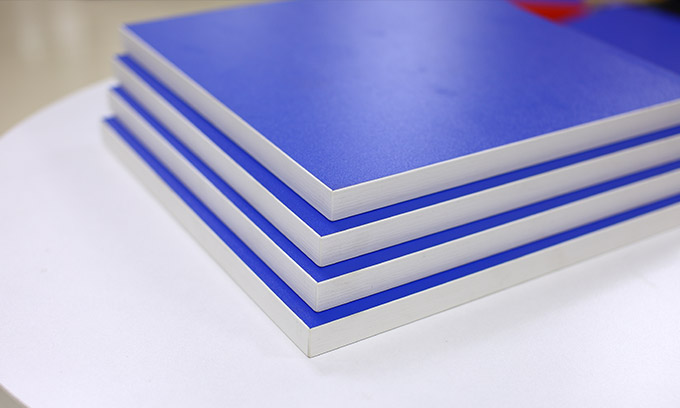

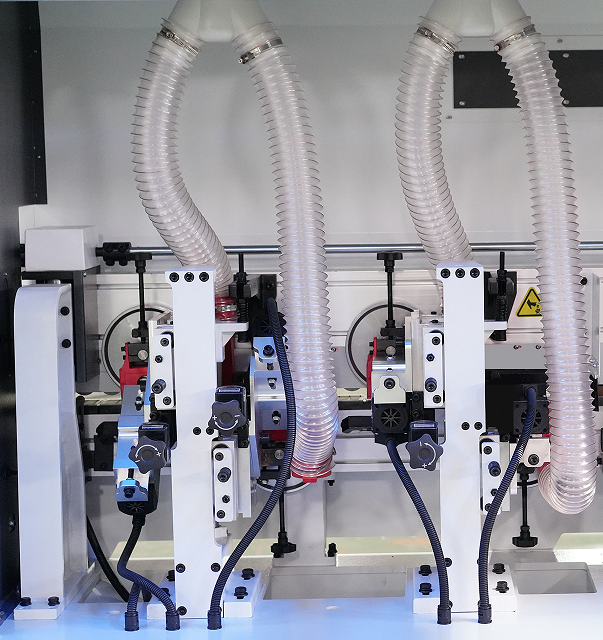

Rough & Fine Trimming System

2 pcs High Frequency Motor for Upper and Lower Edge with 0.75 Kw (1 Hp); 18000 Rpm. With 2pcs 6 Teeth R2 Cutters. The Manual 2-axis Position Control of Both Height and Depth Ensures 100% Repeatability. Edge Belt Thickness Change by Manual.

Corner Rounding Unit

Corner rounding unit for soft and postforming workpieces for the processing of the ends of the panel with 0.4-3.0 mm edge material

and 10-60 mm workpiece height, With 2pcs 0.37kw motors. Suitable for straight workpiece edges.

Double Buffing

Upper and lower buffing unit ensures a perfect finish on the edge radius and removes any colour irregularities.

Technical Specifications

| Panel length size | ≥120mm |

| Panel width size | ≥95mm |

| Panel thickness | 10-60mm |

| Edge width | 13-63mm |

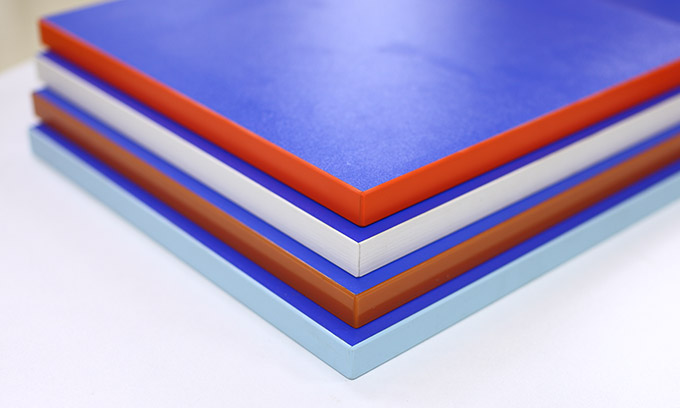

| Edge thickness | 0.4-3.0mm |

| Feed rate | 15-18-20m/min |

| Total power | 24kw |

| Working pressure | 0.65mpa |

| Size | 8050*1000*1700mm |

| Weight | 2700kg |

Applications

Automatic edge banding machine, meet various edge banding needs, the necessary machine for furniture, saving time, labor cost.