At HUAHUA, we are edge banding manufacturer and take pride in delivering cutting-edge solutions for your panel furniture manufacturing needs. Our automatic edge banding machines are constantly optimized to provide exquisite edgebanding, ensuring superior quality and durability. With our state-of-the-art technology and commitment to innovation, we strive to revolutionize the industry. In this article, we will explore the key features of our automatic edge banding machine, highlighting its benefits and how it can enhance your furniture production process.

Well Pre-mill, Half Done

The pre-milling unit in HUAHUA’s automatic edge banding machine plays a crucial role in achieving flawless edgebanding results. By grinding the edges of panels at the beginning, this unit ensures a firm bond between the banding tape and the panel during the later process. With precise pre-milling, you can expect enhanced adhesion, preventing any potential issues with the banding tape peeling off over time. This feature saves you time and effort, enabling a more efficient production workflow.

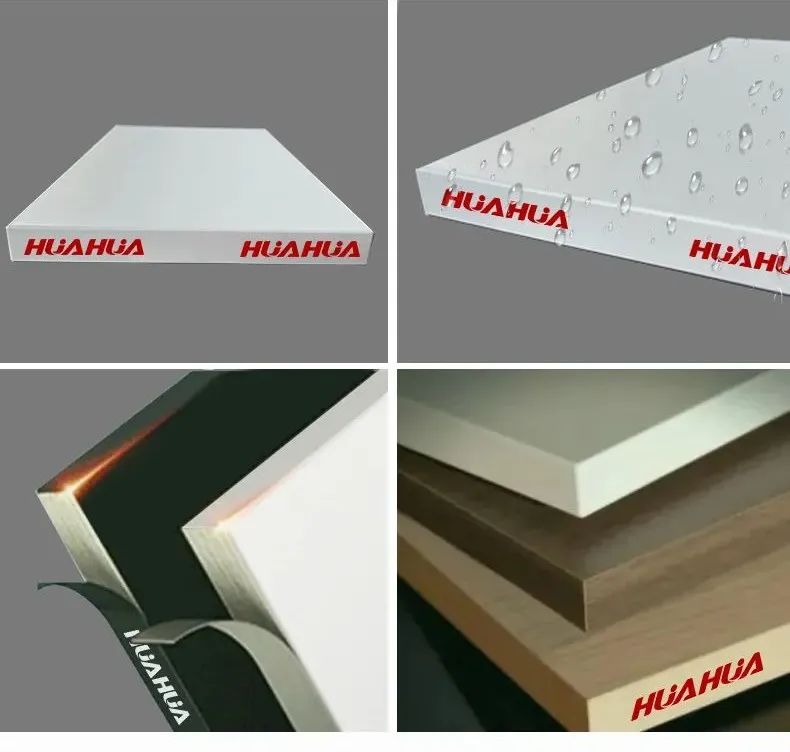

Water-Proof PUR Glue

When it comes to edgebanding, the quality of the adhesive used is paramount. HUAHUA’s automatic edge banding machine utilizes water-proof and damp-proof PUR (polyurethane resin) glue in its gluing device. This advanced adhesive offers exceptional durability, protecting wood panels from potential damage caused by moisture. Whether you’re working with solid wood, veneer core plywood, or MDF, our water-proof PUR glue ensures a long-lasting and reliable bond, extending the lifespan of your furniture.

Auto-track Trimming and Corner Rounding & Polishing

HUAHUA understands the importance of a smooth and polished finish in panel furniture. Our automatic edge banding machine features innovative auto-track trimming technology. Equipped with double trimming discs, the machine automatically tracks panels, removing excessive glue and tape. This process guarantees a flawless appearance, making your furniture more visually appealing and satisfying the demands of the end-market.

Additionally, to help you produce perfect panel furniture, HUAHUA incorporates corner rounding and cloth polishing wheels into its edge banding machine. These features ensure precise corner rounding and a polished surface, elevating the overall quality of your furniture. With HUAHUA’s commitment to flawless edge banding procedures, you can confidently deliver top-notch products to your customers.

Conclusion:

As an edge banding manufacturer, HUAHUA is dedicated to providing superior solutions for your furniture manufacturing needs. Our automatic edge banding machines offer a range of advanced features, from well pre-milling and water-proof PUR glue to auto-track trimming and corner rounding & polishing. With our innovative technology, you can achieve exquisite edgebanding, enhancing the quality and durability of your panel furniture. Trust us for all your edge banding requirements and revolutionize your furniture manufacturing process today.