SKH-680SAZ

SKH-680SAZ

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Features

- Specifications

Functions

Features

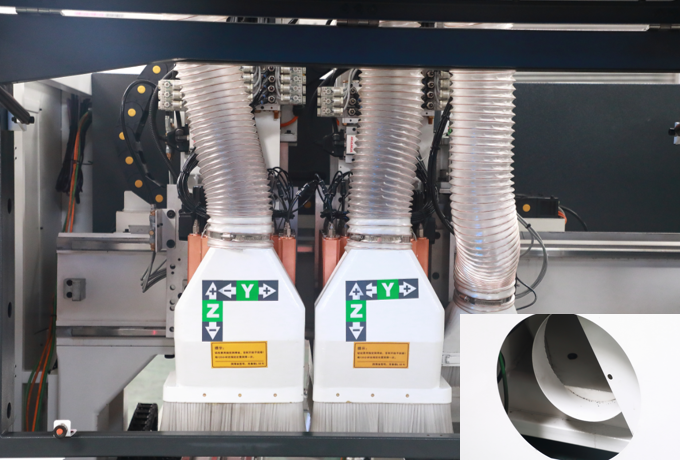

6 Drilling Heads

SKH-680SAZ machine with 4 upper drilling heads + 2 bottom drilling heads plus 4 pcs 3.5kw milling spindles, can do panel 6 sides drilling and 2 sides grooving and milling for greater efficiency.

The machining efficiency is 20% higher than 4 sets drilling heads double working tables cnc drilling machines.

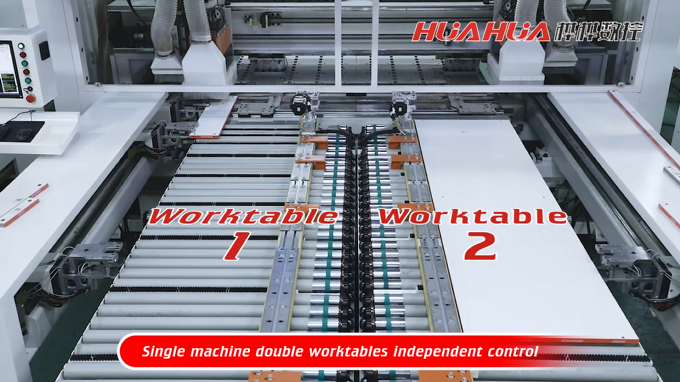

Double worktables with rollers

Single machine double worktables independent control, each station equip with 3m loading and 3m unloading conveyor rollers, can process different panels at the same time, and both station can pass through panel maximum width of 800mm.

The rollers transmission speed reach to 60m/min.

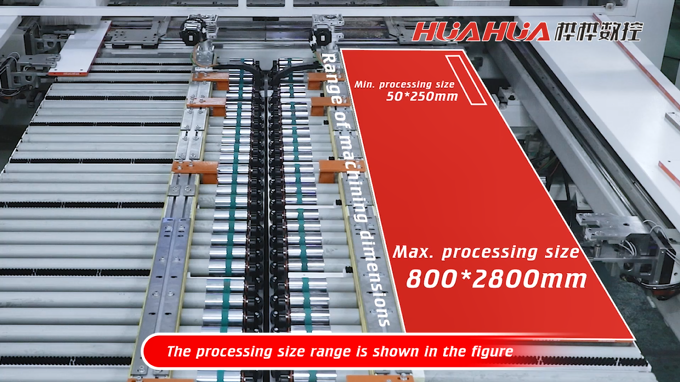

Processing range

Max. processing size: 800*2800mm

Min. processing size: 50*250mm

Suit for mixed orders mass production and connect with automatic production line production.

Two computers linked control

Single machine and two computers linked control, the operator does not need to run left and right to operation. Save time.

Both computers with industrial PC, can connect with internet or wifi, convenient for transfer production data and make remote control service.

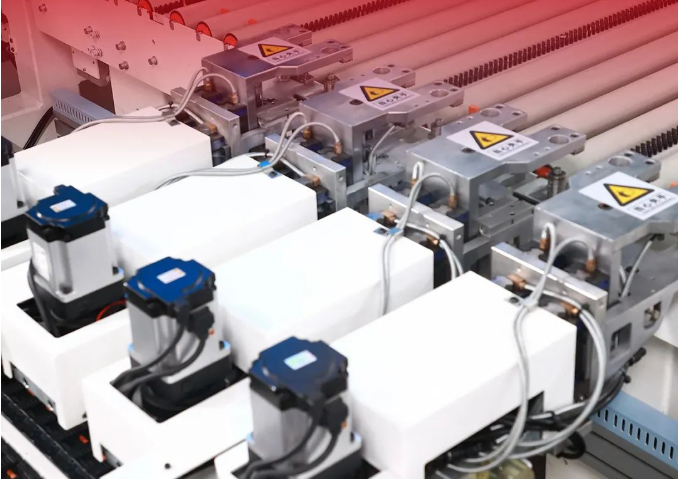

Eight Clamps

HUAHUA’s exclusive and pioneering technology

Each working station with 4 clamps, continuous feeding and processing.

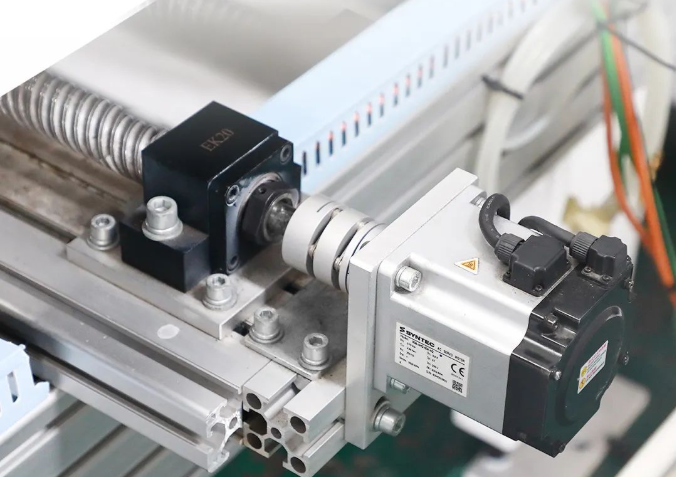

Servo drive system

All functions of the aligning, clamping, transmission, and processing are moved according to the instructions of the servo drive system, which can respond quickly, and have high processing accuracy and good stability

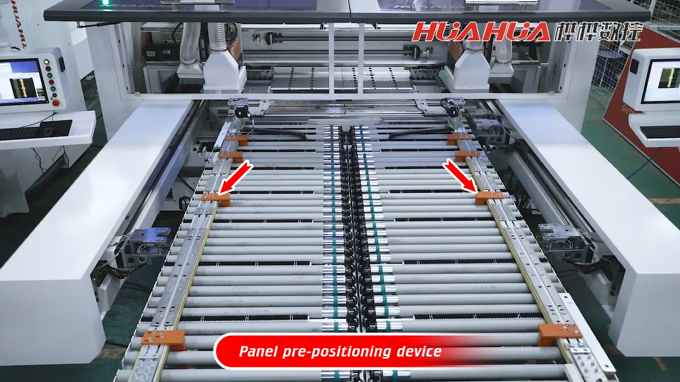

Panel pre-positioning device

The integrated design of the Panel pre-positioning device and the roller, auxiliary panel quick positioning, fast feeding, saving space, and the rubber roller will ensure the plate not damage when conveying.

Ball Screw Driving + Servo Motor Control

Panel pre-positioning device ball screw driving + servo motor control, accurate positioning and aligning.

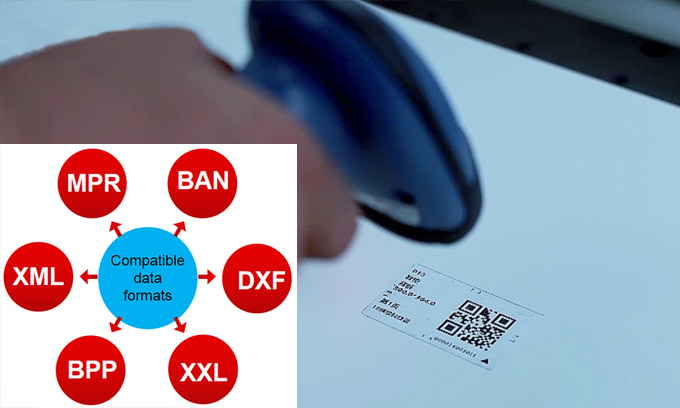

Scan QR Code Loading Processing Files

Support barcode / QR code, scan and automatically load processing graphics files like MPR, DXF, BAN, XML etc.,and automatically generate NC program processing

Compatible with Multiple Data Formats

Convenient and efficient opertion

Efficient Dust Collection

Machine top drilling heads and machine bottom have different vacuuming ports, combinating blowing and vabuuming, the effect of removing dust is strong, reducing the failure rate and maintenance costs.

Optional

SKH-680SAZ machine can option Automatic QR code camera scanning device continuous feeding panels, please contact our sales for more details

Technical Specifications

| Working Stoke & Max. Position Speed: |

X1/X2/X3/X4 axis | 5410mm & 130m/min |

| Y1/Y2/Y3/Y4 axis | 1450mm & 80m/min | |

| Z1/Z2/Z3/Z4 axis | 130mm & 30m/min | |

| U1/U2/U3/U4 axis | 5410mm & 130m/min | |

| V1/V2 axis | 965mm & 80m/min | |

| W1/W2 axis | 110mm & 30m/min | |

| A1/A2 axis | 810mm & 30m/min | |

| Drilling unit: | Vertical drilling bits | Top drilling 12*4 groups, Bottom drilling 9*2 groups |

| Horizontal drilling bits | 8pcs*4 groups | |

| Drilling head motor speed | 2800rpm(r/min) | |

| Drilling head motor power | 2.2KW*6 | |

| Spindle unit: | Spindle power | 3.5KW*4 |

| Tool holder diameter | 1/2′ | |

| Spindle | ER25 | |

| Spindle rotate speed | 18000rpm | |

| Processing Size Range: |

Panel length | 50-5000mm |

| Panel width of double worktable | 50-800mm | |

| Min. processing size | 250*50mm | |

| Panel thickness | 10-50mm | |

| Other Data: | Working table height | 960mm |

| Total Power | 46.82kw | |

| 380V/50Hz-3Phase | 380V/50Hz | |

| working air pressure | 0.7-0.8Mpa | |

| Weight | 5750KG | |

| Overall size | 6180X4390X2270mm |

Applications

6 sides drilling, grooving, meet all kinds of furniture production needs.